Our Blog

Check out our innovative pump solutions and industry insights to see what's new in the pumping industry. Stay up to date with the latest trends and news in the world of pumping technology by following our pumping technology blog.

- Home

- Blog

1 HP Well Pump Tips for Optimal Performance and Maintenance?

When it comes to maintaining a 1 hp well pump, attention to detail is crucial. Expert Jim Anderson, a well-known figure in the water system industry, emphasizes, “Regular maintenance is the key to longevity for pumps”. This statement highlights the importance of routine checks and care for optimal performance.

Proper installation plays a significant role in the efficiency of your 1 hp well pump. It should be placed at the right depth to ensure it draws sufficient water without straining. Many homeowners overlook this simple detail. They may install it too shallow or deep, which can lead to inefficiencies. Also, neglecting the power supply can create unnecessary challenges.

Troubleshooting is another essential aspect. If your pump is noisy or not performing well, it may indicate a problem. Being aware of these signs is vital. Homeowners often blame the pump's quality rather than considering user error or maintenance lapses. Reflecting on these factors can improve the overall functionality of a 1 hp well pump.

1 HP Well Pump Overview: Understanding Types and Applications

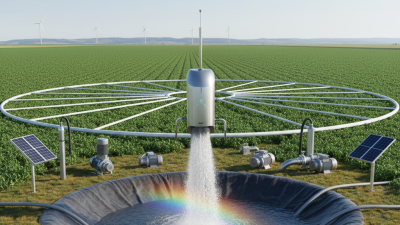

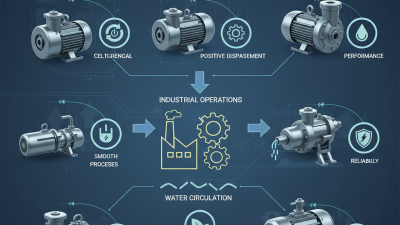

A 1 HP well pump is essential for various applications, especially in residential settings. These pumps are designed to extract water from wells and provide a consistent flow for irrigation, household use, and more. Understanding the types of 1 HP well pumps is crucial. Submersible pumps are submerged underwater and are efficient for deeper wells. Jet pumps, on the other hand, are suitable for shallower wells and operate above ground. Each type has unique advantages depending on the specific needs.

Maintenance plays a significant role in a well pump's performance. Regular checks on the pump's pressure gauge can help identify issues early. Dirty filters can reduce efficiency, so cleaning them is important. Users often forget this tip, leading to unnecessary wear. Additionally, monitoring water quality is vital. Contaminants can harm not just the pump but also water supply. Some people overlook this crucial aspect, causing larger problems that are hard to fix later. Overall, understanding these details helps ensure optimal performance and longevity of a 1 HP well pump.

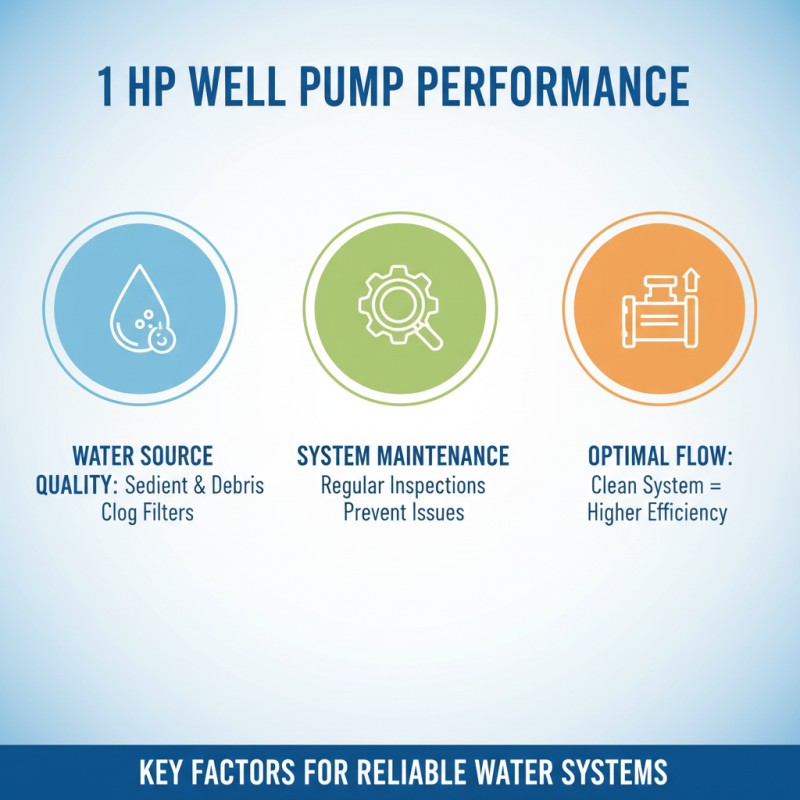

Key Factors Influencing 1 HP Well Pump Performance and Efficiency

One horsepower well pumps play a crucial role in various water systems. Their performance hinges on several key factors. First, the quality of the water source significantly impacts efficiency. Sediment and debris can clog filters and hinder flow rates. Regular inspections help spot these issues before they escalate.

Another important aspect is the pump's depth. If the pump is too deep, it may struggle to draw water effectively. This can lead to increased energy consumption and wear on the motor. Installing a flow rate gauge can provide valuable insights into the system's behavior over time. Maintaining the right depth ensures optimal performance.

Piping and fittings also matter. Leaks can lead to significant water loss and reduce pressure. Using proper sealing techniques is essential. Moreover, checking connections regularly aids in early detection of problems. Neglecting these aspects often leads to frustration during peak usage times.

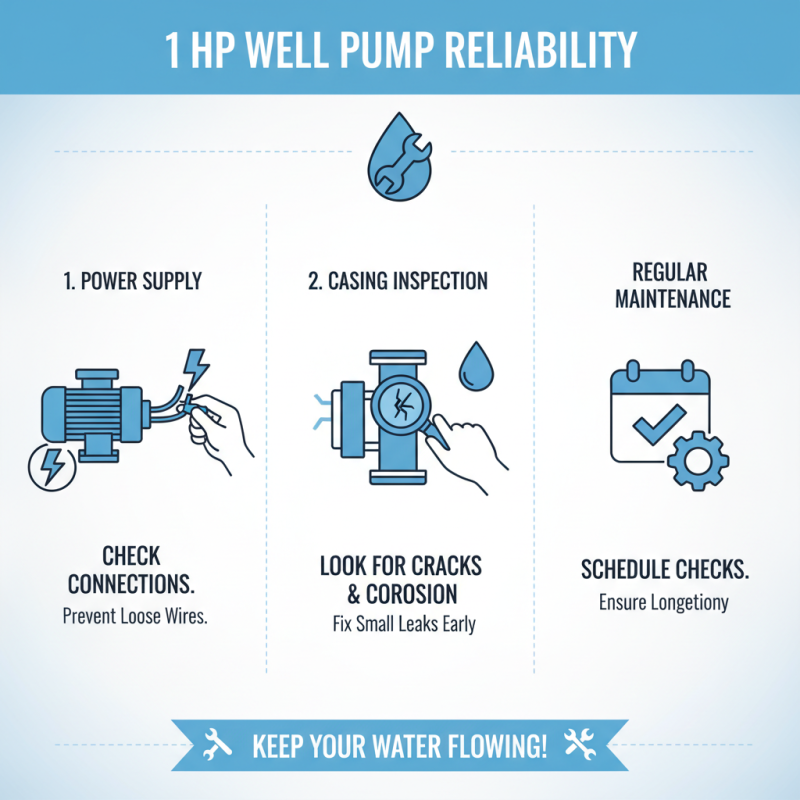

Routine Maintenance Practices to Extend 1 HP Well Pump Lifespan

Regular maintenance of a 1 HP well pump is crucial for its reliability. Start by checking the power supply connections. Loose wires can lead to motor failure. Regularly inspect the pump’s casing for cracks or corrosion. Small leaks can escalate quickly; fix them before they worsen.

Change the pump’s filter every few months. A clogged filter reduces efficiency and puts extra load on the pump. Cleaning the impeller is also essential. Debris buildup affects flow rates. Pay attention to the pressure gauge. An unusual reading may indicate a problem.

Don’t forget about water quality. High sediment levels can wear down components. Test your water regularly. If necessary, install a sediment filter. Lastly, review your pump's operating hours. Overuse can shorten its lifespan. Schedule downtime for a thorough inspection.

Troubleshooting Common Issues in 1 HP Well Pumps for Optimal Use

When dealing with 1 HP well pumps, users often face common issues that hinder performance. One prevalent problem is insufficient water output. According to a report by the Water Well Journal, nearly 30% of well pump users experience this issue due to various factors, such as clogged filters or low water levels. Regularly checking these components can help maintain optimal performance. Ignoring these signs may lead to greater inefficiencies or even pump failure.

Another frequent challenge is pump cycling. This occurs when the pump turns on and off too frequently. Research from the National Ground Water Association indicates that rapid cycling can shorten the lifespan of the pump. Users should inspect the pressure switch settings and ensure there are no leaks in the system. A leak as small as a drip can cause significant cycling issues. Addressing these concerns early pays off in the long run.

Vibration is yet another common issue. It can indicate misalignment or wear within the pump. According to a study by the American Society of Civil Engineers, excessive vibration can lead to premature pump failure. Regular monitoring and routine maintenance are essential. Ensuring that all connections are secure and checking for wear can mitigate these problems before they escalate.

1 HP Well Pump Tips for Optimal Performance and Maintenance

| Maintenance Tip | Frequency | Common Issues | Troubleshooting Steps |

|---|---|---|---|

| Check the power supply | Monthly | Pump not starting | Ensure power is connected; check circuit breakers. |

| Inspect for leaks | Quarterly | Loss of water pressure | Check all connections and pipes for leaks. |

| Clean the pump filter | Every 6 months | Reduced water flow | Remove and clean filter; replace if damaged. |

| Test pressure switch | Annually | Pump cycles frequently | Adjust or replace pressure switch if necessary. |

| Inspect electrical components | Annually | Pump not operating | Check wiring for damage; replace defective parts. |

Industry Standards and Guidelines for 1 HP Well Pump Installation

When installing a 1 HP well pump, following industry standards is crucial. According to the National Water Well Association, proper installation affects not only the pump's efficiency but also its lifespan. An error here can lead to significant issues. For instance, incorrect sizing can cause the pump to work harder, leading to increased wear and tear.

One common tip is to ensure the pump is installed at the right depth. The optimal depth should accommodate the static water level and allow for some fluctuations. This helps prevent the pump from running dry, a common problem that can cause severe damage. Over time, ignoring this can lead to costly repairs or replacements.

Regular maintenance is equally essential. Scheduling inspections every six months is advisable. During these inspections, check for leaks and assess the motor's performance. Indicators like unusual noises can signal underlying issues. Remember, keeping a log of maintenance activities can reveal patterns. Recognizing these can help prevent future problems.

1 HP Well Pump Performance and Maintenance Guidelines

Related Posts

-

Understanding the Benefits of Using a 1 Hp Well Pump for Efficient Water Supply

-

2025 Top 10 Best 1 HP Well Pumps for Efficient Water Supply

-

2026 How to Choose the Right 2 Submersible Pump for Your Needs?

-

Top 10 Deep Well Water Pumps for Efficient Water Extraction?

-

Top 10 Bore Pump Types for Efficient Water Extraction Techniques

-

7 Best Industrial Water Pumps: Top Choices for Efficiency and Performance