Our Blog

Check out our innovative pump solutions and industry insights to see what's new in the pumping industry. Stay up to date with the latest trends and news in the world of pumping technology by following our pumping technology blog.

- Home

- Blog

What is a Submersible Motor and Its Applications?

The submersible motor is a crucial innovation in various industries, particularly in water management. These motors are designed to operate underwater. According to the latest industry reports, the global submersible motors market is expected to reach $3 billion by 2025. This growth is driven by increasing demand in agricultural irrigation and sewage treatment.

In many applications, submersible motors provide reliable and efficient operation. They are commonly used in deep wells and boreholes. However, challenges do exist. For instance, these motors can face issues with thermal management. Poor cooling can lead to failures, which complicates maintenance.

Moreover, the technology behind submersible motors continues to evolve. Despite advancements, many users still experience unexpected downtime. The balance between efficiency and longevity remains a topic of discussion. Ensuring optimal performance requires careful consideration of operating conditions. Better design and materials may be key to overcoming these challenges.

Definition and Structure of Submersible Motors

Submersible motors are innovative devices designed to operate underwater. They are commonly used in various applications, including water wells and wastewater systems. Their unique structure allows them to function effectively in harsh underwater environments, where traditional motors would fail.

The core of a submersible motor consists of a sealed casing that protects internal components from water intrusion. This casing is often filled with oil to enhance cooling and lubrication. The motor itself is usually connected to a pump that helps circulate liquids. The compact design allows for easy installation in deep wells or submerged settings. However, maintenance can be tricky due to their underwater location.

Due to their submerged nature, these motors face unique challenges. Corrosion can occur over time, especially if materials are not optimal. Additionally, sealing issues can arise, leading to potential failures. Keeping an eye on performance is vital to prevent unexpected breakdowns. Understanding the structure and operation of submersible motors can help in making better choices for specific applications.

Submersible Motor Applications

Working Principles of Submersible Motors

Submersible motors are vital in various industries. Their design allows them to operate underwater without compromising efficiency. These motors often use a sealed casing. This helps prevent water intrusion.

The working principle hinges on electromagnetic induction. When current flows through the motor windings, it generates a magnetic field. This field interacts with the stator and rotor to produce rotation. This process varies in complexity, depending on the motor’s design. For instance, in 2022, the submersible motor market was valued at approximately $3.67 billion, indicating growing reliance on these systems.

Applications are extensive. They are commonly used in oil extraction, mining, and water supply. Despite their importance, challenges remain. Manufacturers must continuously address reliability and durability issues, especially in corrosive environments. The effectiveness of submersible motors can be hindered by sediment and debris, leading to performance drops. Awareness of these factors is essential for optimizing function in challenging settings.

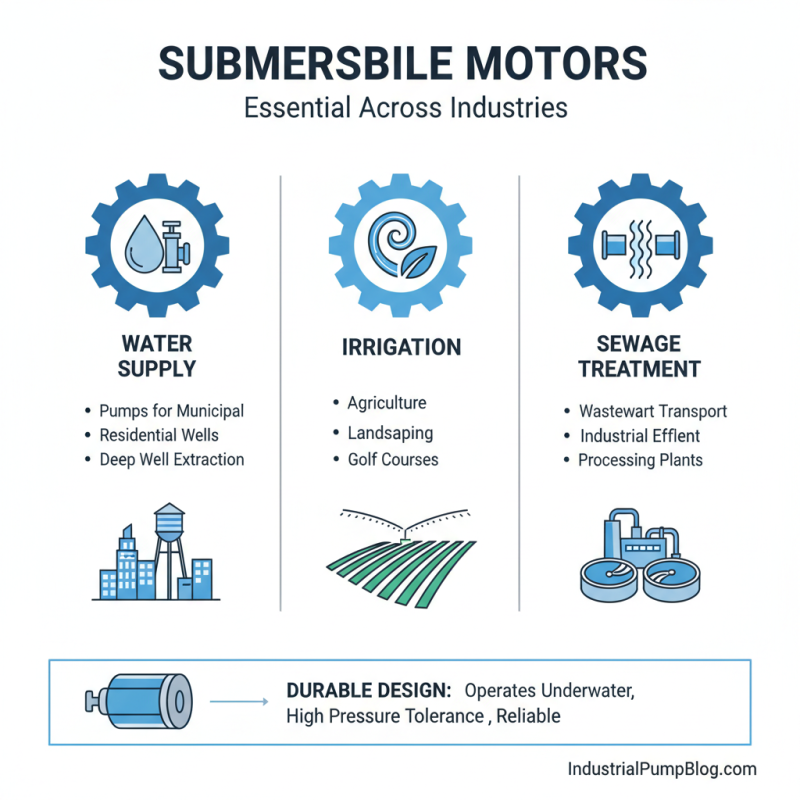

Common Applications in Various Industries

Submersible motors are crucial in various industries. They operate underwater, providing efficiency and reliability. These motors are often used in pumps for water supply, irrigation, and sewage treatment. Their design allows them to withstand pressure and operate in challenging environments.

In agriculture, submersible motors power irrigation systems. Farmers rely on them to ensure their crops receive adequate water. This technology is vital for productivity. However, improper maintenance can lead to failures. Some farmers might overlook this aspect, resulting in costly downtime.

Moreover, in the oil and gas industry, these motors help in extracting resources from deep underground. They are used in offshore drilling applications as well. The efficiency gained can be significant. Yet, the risks involved should not be underestimated. Equipment failures can lead to environmental and financial repercussions. Addressing these challenges is essential for sustainable operations.

Advantages and Disadvantages of Using Submersible Motors

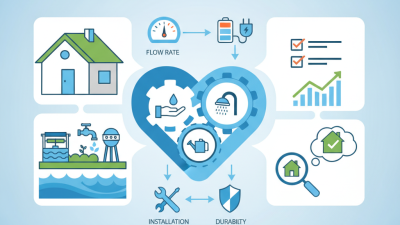

Submersible motors are widely used in various industries. They are efficient in moving fluids from deep underground or underwater locations. Their primary advantage is their ability to operate submerged, reducing the need for complex surface equipment. In fact, the Global Submersible Pump Market is expected to reach over $17 billion by 2027, according to industry reports.

One major advantage of submersible motors is their energy efficiency. They often consume less power compared to traditional motors. This translates to lower operational costs over time. However, they can be challenging to maintain. Once submerged, routine checks are not easy to perform. Also, if a failure occurs, extracting the motor can be a complex process, potentially leading to costly repairs.

Tips: Always consider the type of fluid being pumped. Some liquids can cause corrosion. Also, be aware of possible changes in temperature and pressure. These factors can affect the motor's lifespan.

Another point to ponder is the environmental impact. While submersible motors are efficient, they can be detrimental to aquatic ecosystems if not handled properly. Leaks or failures can introduce pollutants. It’s crucial to weigh these risks against the benefits when choosing submersible motors for projects.

Maintenance and Safety Considerations for Submersible Motors

Submersible motors are vital for various applications, yet their maintenance is often overlooked. Regular inspections can prevent costly breakdowns. According to recent industry reports, nearly 30% of motor failures result from inadequate maintenance practices.

Tip: Schedule quarterly maintenance checks to identify issues early. This ensures optimal performance and enhances longevity.

Improper handling during installation can lead to significant problems later. Many operators underestimate the importance of electrical connections and sealing mechanisms. A survey revealed that 25% of motor failures stem from faulty connections. Such oversights can lead to outages and increased operational costs.

Tip: Always verify electrical connections during installation. A five-minute check can save hours of downtime.

Water ingress poses another major risk. Moisture can lead to corrosion and short circuits. Despite being called submersible, these motors need protection against extreme conditions. Experts recommend using moisture-resistant materials to extend service life. Regular cleaning is also crucial to prevent debris buildup.

Tip: Clean your motor casing monthly to avoid clogs. A clean environment promotes better functionality.

Related Posts

-

Top 10 Benefits of Submersible Motors for Efficient Pumping Solutions?

-

Why You Should Use a Mini Water Pump for Your Home and Garden Needs?

-

What is the Best Water Pump for Home Use and How to Choose One

-

Essential Guide to Choosing the Perfect Well Water Pump for Your Home Needs

-

Maximizing Efficiency: How Submersible Pumps Revolutionize Water Management in Agriculture

-

Unlocking Efficiency: The Ultimate Guide to Choosing the Right Motor Pump for Your Needs