Choosing the right Industrial Water Pump for your business is a critical decision that can significantly impact your operations and efficiency.

With a multitude of options available on the market, it's essential to navigate the complexities of pump selection effectively.

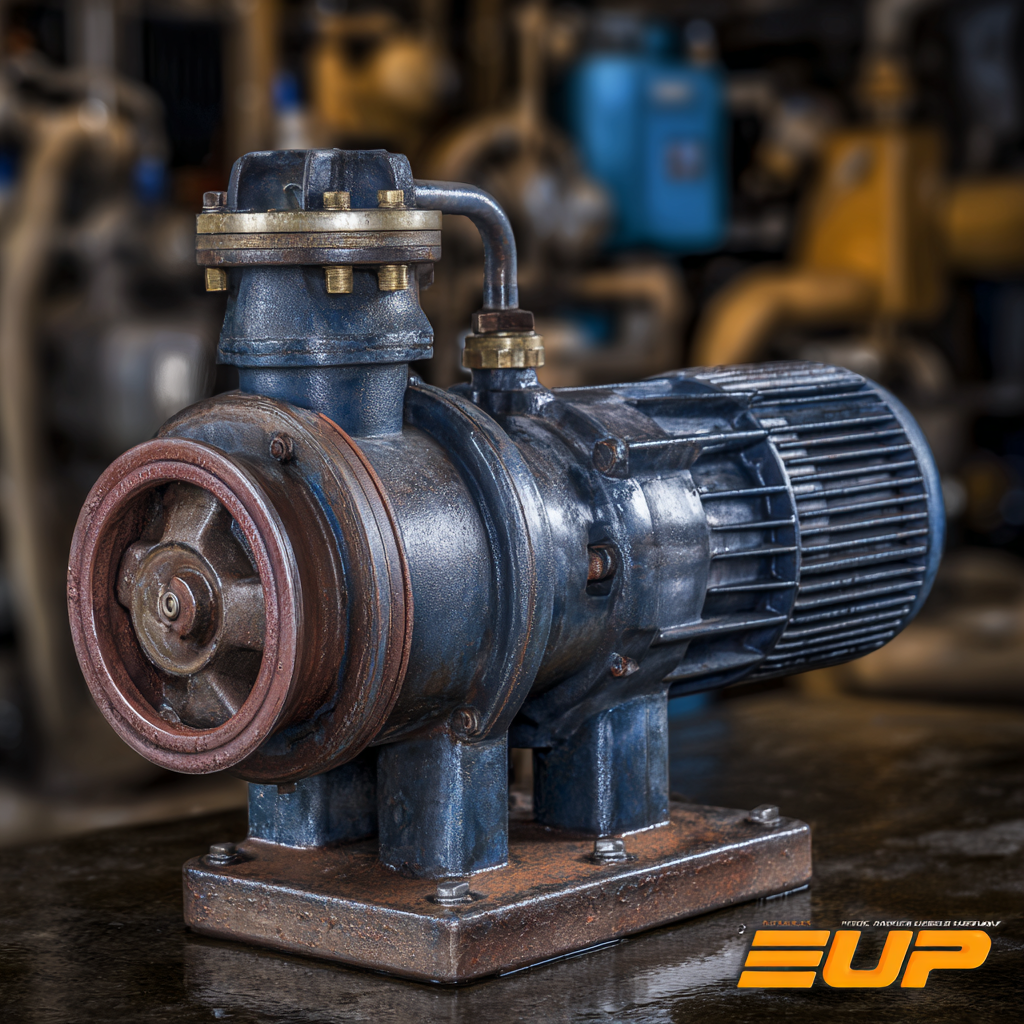

An Industrial Water Pump is not just a piece of equipment; it plays a vital role in various industrial processes, from manufacturing to agriculture.

Understanding the specific requirements of your application, including flow rate, pressure, and compatibility with the fluids being handled, is fundamental.

In this guide, we will explore seven essential secrets that will empower you to make informed decisions, ensuring that you select the best Industrial Water Pump tailored to your business needs.

Whether you're upgrading existing equipment or investing in new technology, these insights will help streamline your pumping solutions and enhance productivity.

Choosing the right Industrial Water Pump for your business is a critical decision that can significantly impact your operations and efficiency.

With a multitude of options available on the market, it's essential to navigate the complexities of pump selection effectively.

An Industrial Water Pump is not just a piece of equipment; it plays a vital role in various industrial processes, from manufacturing to agriculture.

Understanding the specific requirements of your application, including flow rate, pressure, and compatibility with the fluids being handled, is fundamental.

In this guide, we will explore seven essential secrets that will empower you to make informed decisions, ensuring that you select the best Industrial Water Pump tailored to your business needs.

Whether you're upgrading existing equipment or investing in new technology, these insights will help streamline your pumping solutions and enhance productivity.

When selecting the best industrial water pump for your business, understanding key technical specifications is crucial to ensuring optimal performance and efficiency. One of the primary specifications to consider is the flow rate, which indicates how much water the pump can move in a given time frame, typically measured in gallons per minute (GPM) or liters per second (L/s). Depending on your application—whether it’s for irrigation, cooling systems, or wastewater management—matching the pump's flow rate to your specific needs is vital for maintaining operational efficiency.

Another critical specification is the pump's head pressure, which is the maximum height the water can be pumped vertically. This is essential for applications where water needs to be lifted to significant heights. Understanding the Total Dynamic Head (TDH), which factors in both the static lift and the friction losses in the piping system, is imperative. Additionally, consider the pump material and design parameters, such as the type of impeller, which can affect durability and performance in various conditions. By carefully analyzing these technical specifications, businesses can make informed decisions to select the right pump for their unique requirements.

| Specification | Importance | Recommended Range |

|---|---|---|

| Flow Rate (GPM) | Determines the volume of water supplied | 50 - 500 GPM |

| Total Dynamic Head (TDH) | Measures the total height the pump can lift water | 10 - 100 ft |

| Pump Efficiency | Indicates energy consumption versus output | 70% - 85% |

| Motor Power (HP) | Dictates the power required to operate the pump | 1 - 15 HP |

| Material Type | Impacts durability and compatibility with water types | Cast Iron, Stainless Steel, Plastic |

| Inlet/Outlet Size | Affects pipe compatibility and flow rate | 2" - 8" |

| Self-Priming Capability | Necessary for situations with fluctuating water levels | Yes / No |

When selecting the best industrial water pump for your business, understanding the flow rate requirements is crucial for ensuring optimal performance. According to a recent report by the Hydraulic Institute, selecting a pump with the appropriate flow rate can improve system efficiency by over 20%. Flow rate, measured in gallons per minute (GPM) or liters per second (L/s), dictates the volume of water a pump can move. Failing to accurately evaluate this requirement can lead to either pump underperformance or unnecessary energy consumption, ultimately driving up operational costs.

To determine the correct flow rate for your application, consider factors such as the end-use demands, the system's total dynamic head, and the characteristics of the fluid being pumped. For example, a study by the American Society of Mechanical Engineers indicates that pumps operating at 75% of their best efficiency point can save businesses more than $4,000 per year in energy alone. Accurate flow rate assessment not only leads to the right pump selection but also ensures that your industrial processes remain efficient and cost-effective.

When selecting the best industrial water pump for your business, assessing pump material compatibility with your specific industry needs is crucial. Different industries demand different materials to withstand the unique challenges they present, such as corrosive substances, high temperatures, or varying pressures. Understanding the environmental conditions in which the pump will operate can help you choose a material that offers longevity and high performance. For instance, pumps used in chemical processing may require materials that resist corrosion, while those in food and beverage applications may need to meet stringent sanitary standards.

The growing demand in the pump market highlights the importance of material compatibility further. As the ISO and ANSI pump markets are projected to experience significant growth, reaching $5.207 billion by 2032, businesses must stay ahead by making informed choices. Moreover, the expansion in the metering pump market, anticipated to exceed $7.8 billion by 2024, exemplifies the trend toward precision equipment that integrates digital controllers for accurate measurement and real-time monitoring. Selecting the right materials not only ensures compliance with industry regulations but also enhances operational efficiency and reduces maintenance costs in the long run.

When selecting an industrial water pump, energy efficiency should be at the forefront of your considerations. Water pumps are vital components in various industries, and their energy consumption can significantly impact operational costs. The energy efficiency rating of a water pump not only indicates how much energy it consumes to perform its function but also reflects its overall performance and reliability. Higher efficiency ratings typically mean lower energy costs over time, allowing businesses to allocate resources more effectively.

Moreover, pumps with higher energy efficiency ratings often come with advanced technology that enhances their longevity and reduces maintenance requirements. This not only helps in cutting down on energy bills but also minimizes the frequency of repairs and replacements, leading to increased productivity. Investing in energy-efficient pumps can result in substantial savings, making it a crucial factor for businesses aiming to optimize their operations while being environmentally conscious. In summary, when choosing an industrial water pump, prioritizing energy efficiency ratings not only supports your operational efficiency but also contributes to a more sustainable future.

When selecting an industrial water pump, it’s crucial to consider not just the initial performance but also the maintenance and service aspects that ensure long-term reliability. Regular maintenance is essential for preventing unexpected downtime and costly repairs. Developing a comprehensive maintenance schedule tailored to the specific requirements of your pump can significantly extend its lifespan. This includes routine inspections, monitoring of key components, and immediate attention to any signs of wear and tear. Proper lubrication, checking seals, and ensuring that filters are clean can keep the pump operating at optimal efficiency.

Moreover, choosing a pump with accessible service options is crucial for keeping operations running smoothly. Engage with manufacturers or suppliers that offer robust support services, as this can facilitate quick troubleshooting and repairs. Having a clear line of communication with service teams ensures that any issues can be addressed promptly, minimizing disruption to your business. Moreover, investing in training for staff on maintenance procedures further enhances reliability. Emphasizing these service considerations during the selection process can lead to substantial savings and operational efficiency in the long run.

TradeManager

Skype

VKontakte