In the dynamic landscape of industrial operations, the selection of the right equipment is crucial for efficiency and productivity, with the

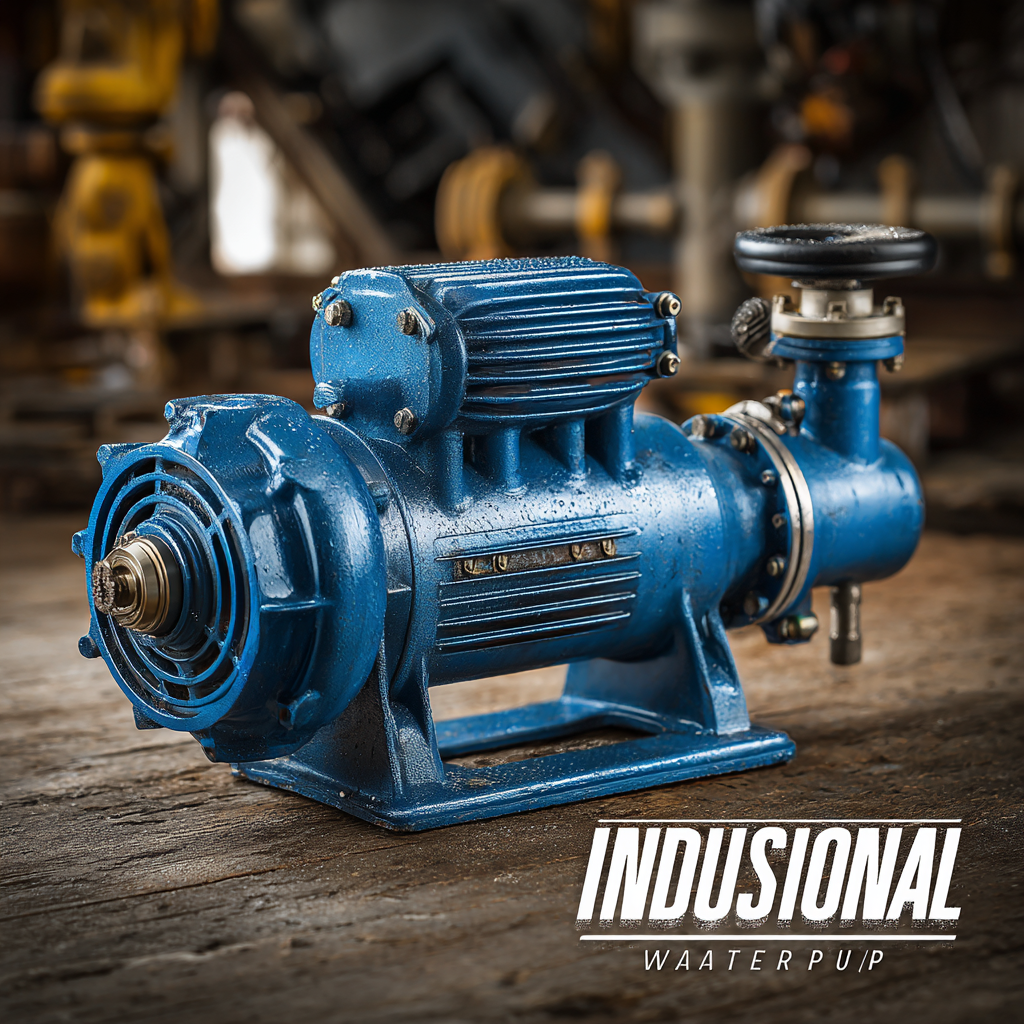

Industrial Water Pump

being a key component in many sectors. According to a report by MarketsandMarkets, the global industrial water pump market is projected to reach

USD 66.4 billion by 2025, driven by the increasing demand for water management in industries such as oil and gas, construction, and manufacturing.

This growth underscores the importance of understanding the critical features of the best industrial water pumps, which can significantly impact operational performance and maintenance costs.

By delving into the industry standards and compelling reasons behind the latest innovations in pump technology, businesses can make informed choices that enhance their water management practices and contribute to sustainable development initiatives.

When selecting industrial water pumps, understanding key technical specifications is essential for ensuring optimal performance and reliability. One of the most critical features to consider is pump efficiency, which directly impacts operational costs. Look for pumps that boast high efficiency ratings, especially those designed to minimize energy consumption while maximizing flow rates.

Another important specification is the materials used in the construction of the pump. For applications in corrosive environments, such as chemical processing or marine projects, pumps made from durable, corrosion-resistant materials are vital. Additionally, the ability of the pump to handle various fluids, including solids and slurries, can significantly enhance its versatility in industrial applications.

Moreover, advancements in technology have led to the development of intelligent pumps that incorporate data-driven solutions for monitoring and optimization. This capability can improve maintenance by predicting failures before they occur and enhancing overall system performance. As the demand for cutting-edge pump technology grows, staying informed about these specifications is crucial for making informed purchasing decisions.

| Specification | Description | Importance |

|---|---|---|

| Flow Rate | Volume of water pumped per unit time, typically measured in GPM (gallons per minute) or L/min (liters per minute). | Critical for determining the pump’s capacity to meet operational needs. |

| Head Pressure | The maximum height the pump can raise water, measured in feet or meters. | Essential for ensuring sufficient water delivery to required locations within a system. |

| Power Source | Type of energy that powers the pump, such as electric, diesel, or solar. | Influences operational costs and suitability for specific environments. |

| Material Construction | Materials used in the pump’s construction, such as stainless steel, cast iron, or plastic. | Determines durability, corrosion resistance, and suitability for different liquids. |

| Efficiency Rating | Ratio of hydraulic power to the mechanical energy consumed, expressed as a percentage. | Higher efficiency leads to lower operational costs and better performance. |

| Pump Type | Type of pump, such as centrifugal, diaphragm, or submersible. | Affects the pump’s operating principles and suitability for specific applications. |

| Dimensions and Weight | Physical size and weight specifications of the pump. | Important for installation space and portability considerations. |

| Temperature Range | Operating temperature limits of the pump. | Critical for ensuring performance in various environmental conditions. |

When selecting the best industrial water pump, evaluating its efficiency is crucial. Two critical metrics that define pump efficiency are flow rate and head pressure.

Flow rate, typically measured in gallons per minute (GPM) or liters per second (L/s), indicates how much water the pump can move in a given timeframe. According to the Hydraulic Institute, optimal flow rates can range significantly depending on the application, but industrial pumps generally perform best within the 10 to 500 GPM range, delivering efficiency that can reduce operational costs significantly.

Head pressure, on the other hand, refers to the height the pump can raise water and is measured in feet or meters. It is vital for determining the pump's ability to overcome resistance in the piping system and reach the intended application site. Research from the American Society of Mechanical Engineers (ASME) shows that a well-designed pump should maintain a head pressure that aligns with system demands, ensuring fluid transport without excessive energy consumption. For most industrial applications, pumps with a head pressure ranging from 50 to 200 feet are preferred, striking a balance between performance and energy efficiency.

By focusing on these two aspects—flow rate and head pressure—industries can select pumps that not only meet operational requirements but also contribute to long-term sustainability goals.

When selecting an industrial water pump, the choice of materials and construction is crucial for durability and long-term performance.

Pumps are frequently exposed to harsh environments, including corrosive chemicals and extreme temperatures. Therefore, manufacturers often use high-grade materials such as stainless steel, cast iron, or specialized polymers to enhance resistance against wear and corrosion. Stainless steel is particularly favored for its ability to maintain structural integrity over time, making it an ideal choice for applications requiring high hygiene standards such as food processing or water treatment.

In addition to the material, the construction methods employed in water pump design significantly influence their lifespan and reliability. Precision engineering ensures that components fit together seamlessly, minimizing the risk of leaks and mechanical failures.

Furthermore, features such as double seals and advanced bearings can provide additional protection against contamination and wear. By focusing on these construction considerations, businesses can invest in water pumps that not only meet their operational demands but also prove cost-effective by reducing maintenance needs over time.

When selecting an industrial water pump, understanding energy consumption metrics is crucial for ensuring operational efficiency and cost-effectiveness. Assessing the energy consumption involves evaluating the pump's efficiency at various operating points. A pump with a high efficiency rating will convert more electrical energy into hydraulic energy, reducing overall operating costs and energy waste. By focusing on energy metrics, businesses can avoid the hidden costs associated with over-sizing or under-sizing pumps, which not only affect energy consumption but also wear-and-tear on the pump itself.

Moreover, the energy consumption data plays a vital role in sustainability efforts within industrial operations. As industries push towards greener practices, choosing pumps with energy-efficient designs and features becomes increasingly important. Factors such as variable frequency drives (VFDs) that adjust the flow rate to actual demand can vastly improve energy savings. Additionally, understanding long-term energy implications fosters better decision-making for pump maintenance and lifecycle management, ultimately contributing to lower environmental impact and enhanced financial performance.

When considering industrial water pumps, understanding their maintenance requirements and service life is critical for optimizing performance and reducing operational costs. According to the Hydraulic Institute's 2022 Pump Predictor report, proper maintenance can extend the life of industrial pumps by up to 25%. Routine checks, such as monitoring seals and bearings, play a crucial role, as nearly 70% of pump failures are attributed to mechanical issues that can be mitigated with regular maintenance.

Additionally, industry data indicates that the average lifespan of an industrial water pump can range from 15 to 25 years, depending on the type and operating conditions. However, factors such as the fluid characteristics, operating temperatures, and maintenance practices significantly influence this lifespan. An analysis by the American Society of Mechanical Engineers (ASME) suggests that implementing predictive maintenance techniques can reduce unexpected downtime by as much as 50%. These insights highlight the importance of not only selecting the best industrial water pump but also committing to a rigorous and proactive maintenance strategy to maximize service life and reliability.

TradeManager

Skype

VKontakte