Our Blog

Check out our innovative pump solutions and industry insights to see what's new in the pumping industry. Stay up to date with the latest trends and news in the world of pumping technology by following our pumping technology blog.

- Home

- Blog

Understanding the Innovations of Pump Manufacturers in Modern Industrial Applications

The continuous evolution of industrial processes necessitates the adoption of advanced technologies, with pump manufacturers at the forefront of this innovation. According to a report by MarketsandMarkets, the global pump market is expected to reach $65.5 billion by 2025, growing at a CAGR of 4.9%. This growth is driven by the increasing demand for efficient fluid management solutions across various sectors, including oil and gas, water and wastewater treatment, and chemical processing.

Modern pump manufacturers are responding to this demand by integrating digital technologies such as IoT, predictive maintenance, and smart automation into their product offerings. These innovations not only enhance operational efficiency and reliability but also aid in reducing downtime and maintenance costs, positioning pump manufacturers as key players in the transformative landscape of industrial applications.

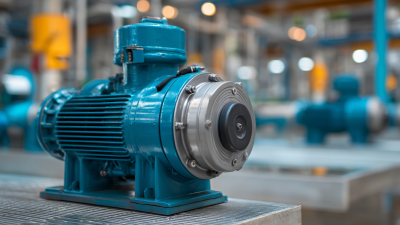

Innovative Design Features in Modern Pump Manufacturing Techniques

In recent years, the pump manufacturing industry has seen significant innovations in design features, aimed at enhancing efficiency, reliability, and sustainability in modern industrial applications. According to a report by Transparency Market Research, the global industrial pumps market is projected to reach $93.11 billion by 2027, underscoring the importance of innovation in this essential sector. One of the notable advancements is the integration of smart technology, which allows pumps to be monitored and controlled remotely, thereby optimizing performance and reducing energy consumption.

Additionally, modern pump designs are increasingly focusing on materials that enhance durability and corrosion resistance. A report from MarketsandMarkets indicates that the demand for advanced materials like carbon composites and specialized alloys is on the rise, driven by the need for pumps that can withstand challenging environments. Furthermore, manufacturers are increasingly adopting modular designs that simplify maintenance and reduce downtime, significantly impacting operational efficiency. This trend not only meets the diverse requirements of various industries but also aligns with sustainability goals by minimizing waste and extending product lifecycles.

Innovative Design Features in Modern Pump Manufacturing Techniques

This chart illustrates the various innovative design features adopted by pump manufacturers in modern industrial applications. The data represents the percentage of manufacturers implementing each feature to enhance efficiency and performance.

Exploring Advanced Materials Used in High-Performance Pumps

In modern industrial applications, the performance of pumps is pivotal, and advancements in materials play a crucial role in enhancing their efficiency and durability. High-performance pumps are increasingly utilizing advanced materials such as ceramics, thermoplastics, and specialized alloys. These materials not only contribute to improved resistance against corrosion and wear but also help in reducing weight and increasing flow efficiency. For instance, the use of ceramic components in pump manufacturing allows for greater longevity and reduced maintenance needs, ultimately leading to cost savings for industries relying on these essential machines.

Tips for selecting the right pump based on materials include assessing the specific application requirements, such as the type of fluids being handled and their operating temperatures. Additionally, considering the environment where the pump will be used is vital; for instance, corrosive environments may necessitate the use of specialized alloys or coatings to ensure optimal performance and lifespan.

Moreover, advancements in composite materials are revolutionizing the design of high-performance pumps. These composites can offer a perfect balance between strength, weight, and chemical resistance, making them ideal for various industrial settings. When evaluating pump options, it is essential to consult with manufacturers about the latest developments in material technologies to ensure the pump meets the specific demands of your application.

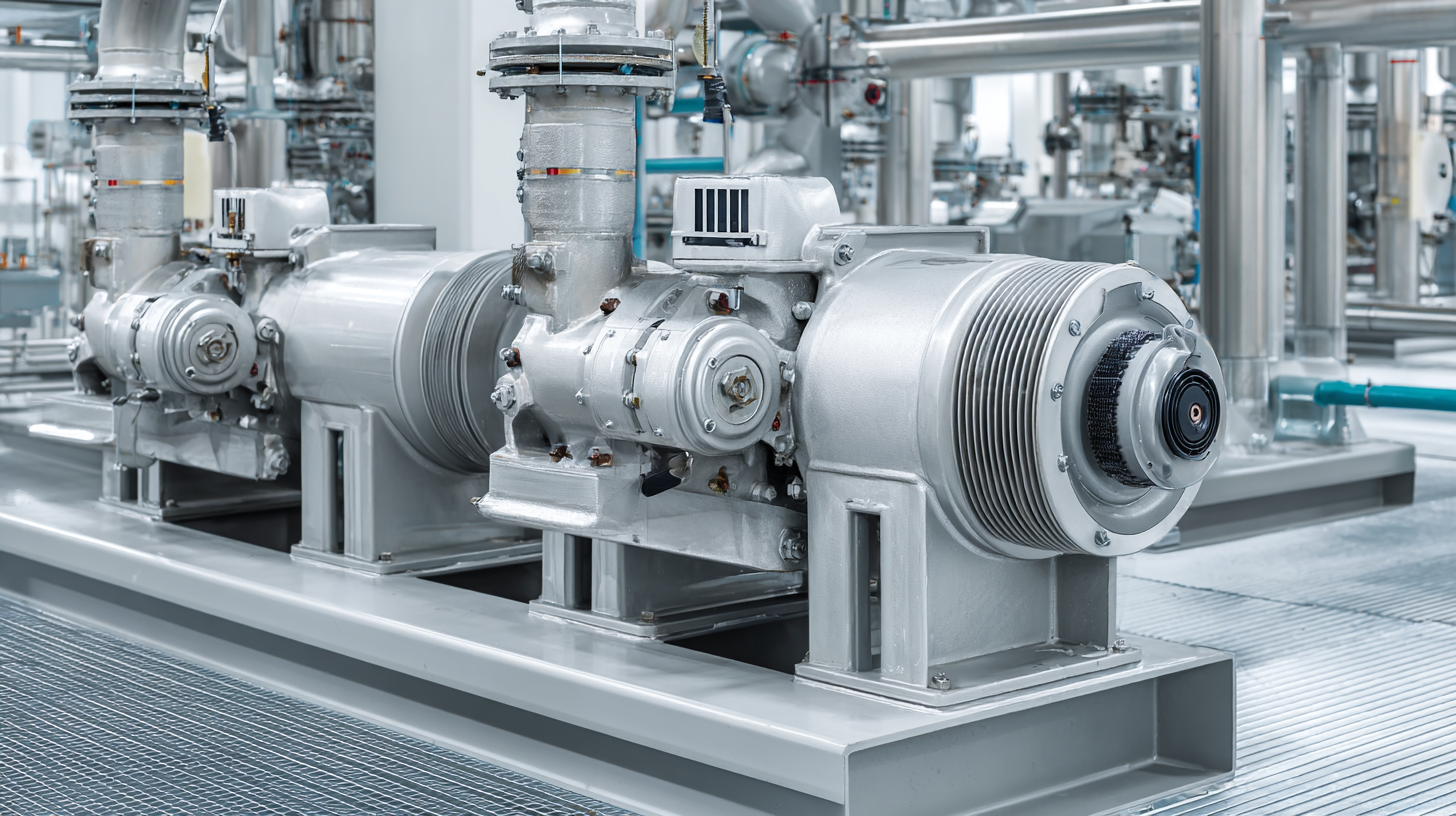

Integration of Smart Technology in Industrial Pump Systems

The integration of smart technology in industrial pump systems represents a significant advancement in manufacturing processes. Modern pump manufacturers are now utilizing Internet of Things (IoT) capabilities to enhance operational efficiency and reliability. By embedding sensors and smart monitoring systems, these pumps can provide real-time data on performance metrics such as flow rates, pressure, and energy consumption. This connectivity allows for predictive maintenance, where potential issues can be detected before they escalate into costly downtimes, thus optimizing the overall lifecycle of the equipment.

Moreover, the use of advanced algorithms and artificial intelligence in pump systems enables better decision-making and automation. Smart pumps can adjust their operations autonomously based on the demands of the system or the specific requirements of the application. This not only leads to energy savings but also minimizes human intervention, reducing the risk of errors and improving safety. As industries strive for higher efficiency and sustainability, the adoption of smart technology in pump systems will play a pivotal role in shaping the future of industrial applications.

Enhancing Energy Efficiency: Pump Innovations for Sustainability

In recent years, the importance of energy efficiency in industrial applications has led pump manufacturers to innovate significantly. A report by the U.S. Department of Energy highlights that pumps account for approximately 20% of the electricity consumed in industrial systems, indicating a substantial opportunity for energy savings. By adopting advanced technologies, manufacturers are developing pumps that not only minimize energy consumption but also enhance overall system performance. For instance, variable frequency drives (VFDs) enable pumps to adjust their speed according to real-time demand, resulting in energy reductions of up to 50% compared to traditional constant-speed pumps.

Moreover, advancements in materials and design have further contributed to improved energy efficiency. According to a study published by the Hydraulic Institute, using high-efficiency impellers and optimized hydraulic designs can improve pump efficiency by 10-15%. Innovations such as smart pumping systems equipped with IoT capabilities allow for better monitoring and predictive maintenance, leading to reduced downtime and improved lifecycle costs. As industry standards shift towards sustainability, these innovations not only address the demand for energy conservation but also support environmental goals by reducing greenhouse gas emissions associated with industrial operations.

Understanding the Innovations of Pump Manufacturers in Modern Industrial Applications - Enhancing Energy Efficiency: Pump Innovations for Sustainability

| Innovation Type | Description | Energy Efficiency Improvement (%) | Applications | Sustainability Impact |

|---|---|---|---|---|

| Variable Frequency Drives (VFDs) | Adjusts motor speed to match demand, reducing energy consumption. | 20-50% | Water treatment plants, HVAC systems | Lower greenhouse gas emissions |

| Smart Pumping Systems | Integrates IoT technology for real-time monitoring and optimization. | 15-30% | Chemical processing, oil & gas | Decreased resource waste |

| Energy Recovery Devices | Captures surplus energy in fluid flow and reuses it. | 25-40% | Geothermal systems, wastewater treatment | Improved energy footprint |

| Enhanced Pump Design | Improved impeller designs and materials to increase efficiency. | 10-20% | Agriculture, mining | Greater durability and less waste |

Customizing Pump Solutions for Diverse Industrial Applications

In the realm of industrial applications, the demand for customized pump solutions has never been more critical. According to the latest report by MarketsandMarkets, the global industrial pump market is projected to reach $84.36 billion by 2025, growing at a CAGR of 4.5%. This growth is driven by the rising need for efficient pumping systems across various sectors, such as oil and gas, water and wastewater, and chemical processing. Manufacturers are now focusing on tailoring pump designs to meet the specific requirements of different industrial processes, thereby enhancing operational efficiency and reducing operational costs.

One of the key innovations in pump manufacturing is the development of modular pump systems that can be easily adapted for various functions. By customizing features such as material selection, pump size, and performance specifications, manufacturers can provide solutions that precisely match the diverse needs of end-users. For example, data from ResearchAndMarkets indicates that smart pump technologies, which include IoT capabilities for real-time monitoring and maintenance, are expected to account for a significant portion of the market share, reflecting a shift towards predictive maintenance and increased reliability in operations. As industries continue to evolve, the ability to offer bespoke pump solutions will be paramount in maintaining competitiveness and efficiency.