Our Blog

Check out our innovative pump solutions and industry insights to see what's new in the pumping industry. Stay up to date with the latest trends and news in the world of pumping technology by following our pumping technology blog.

- Home

- Blog

Unlocking Efficiency: The Ultimate Guide to Choosing the Right Motor Pump for Your Needs

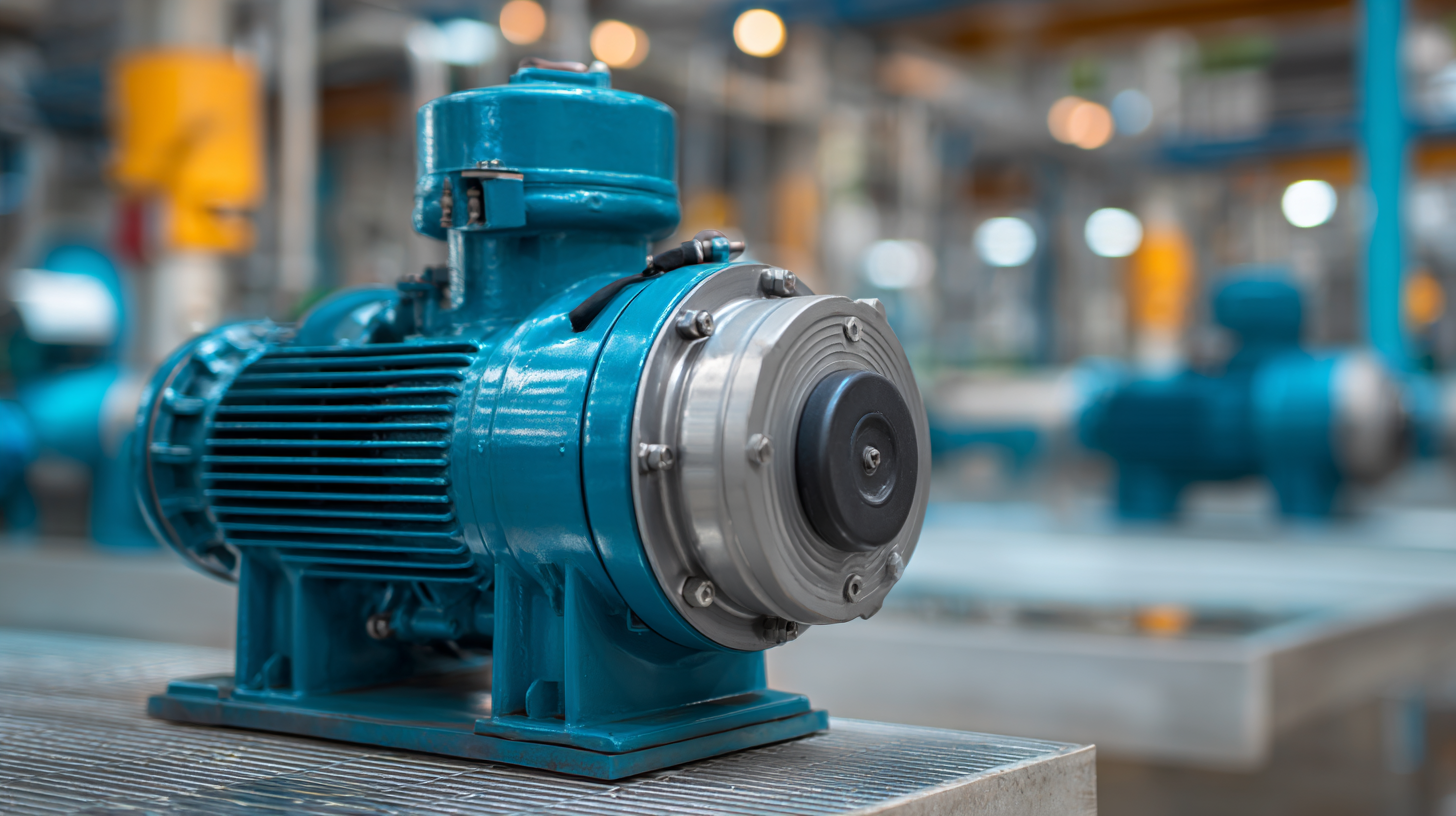

In today's fast-paced world, selecting the right motor pump can significantly enhance operational efficiency across various applications. Whether you are involved in agriculture, industrial processes, or residential water systems, understanding the nuances of motor pump technologies is crucial for optimizing performance and reducing costs. This guide will delve into the key factors to consider when choosing a motor pump, from the type of fluid being moved to the specific requirements of your setup. With a myriad of options available on the market, making an informed choice can be daunting; however, our comprehensive overview will equip you with the knowledge needed to identify the best motor pump tailored to your unique needs. By the end of this guide, you will not only be able to unlock unparalleled efficiency but also gain insights that can lead to long-term savings and enhanced productivity.

Understanding Your Requirements: Analyzing Application Needs for Motor Pumps

When selecting the right motor pump, understanding your specific application needs is crucial. The integration of green energy sources, such as hybrid floating photovoltaic (FPV) systems combined with pumped hydro storage, highlights the importance of efficiency in energy usage. These systems demonstrate how motor pumps can be optimized for applications with significant energy demands, particularly in sectors reliant on renewable resources. In practical terms, analyzing the capacity and design requirements for such systems can lead to enhanced performance and sustainability.

When selecting the right motor pump, understanding your specific application needs is crucial. The integration of green energy sources, such as hybrid floating photovoltaic (FPV) systems combined with pumped hydro storage, highlights the importance of efficiency in energy usage. These systems demonstrate how motor pumps can be optimized for applications with significant energy demands, particularly in sectors reliant on renewable resources. In practical terms, analyzing the capacity and design requirements for such systems can lead to enhanced performance and sustainability.

In agricultural contexts, solar water pumping systems have gained prominence, particularly in humid tropical climates. A thorough evaluation of the energy, design, and environmental aspects of irrigating systems shows the vital role that motor pumps play. Incorporating advanced technologies, such as grid-interactive photovoltaic systems and optimized maximum power point tracking (MPPT), can significantly improve the control and efficiency of water pumping operations. By aligning motor pump selections with these innovative methodologies, users can better meet their operational needs while promoting environmentally friendly practices.

Key Factors to Consider When Selecting a Motor Pump

When selecting a motor pump, several key factors can significantly influence your choice and enhance operational efficiency. First, consider the pump type that best suits your application.

According to the Hydraulic Institute's 2023 report, centrifugal pumps dominate approximately 80% of the market due to their versatility and efficiency in handling various fluids. Whether it’s for agriculture, industrial, or municipal applications, understanding the specific requirements of your setup will guide you in choosing the correct motor pump.

Another essential aspect is the power source. The Energy Information Administration (EIA) reports that electric motor pumps are increasingly popular, offering a reliable and energy-efficient solution compared to gas-powered counterparts. The efficiency of your motor pump can impact operational costs significantly. For example, a well-chosen electric motor can improve overall system efficiency by up to 30%, reducing energy bills and environmental impact.

Tips: Always verify the pump's performance curves and match them with your system's requirements to ensure optimal efficiency. Additionally, consider the maintenance requirements; some pumps may require more upkeep than others, which can affect long-term operational efficiency and cost. Taking the time to evaluate efficiency ratings and operational costs can lead to substantial savings over the life of the pump.

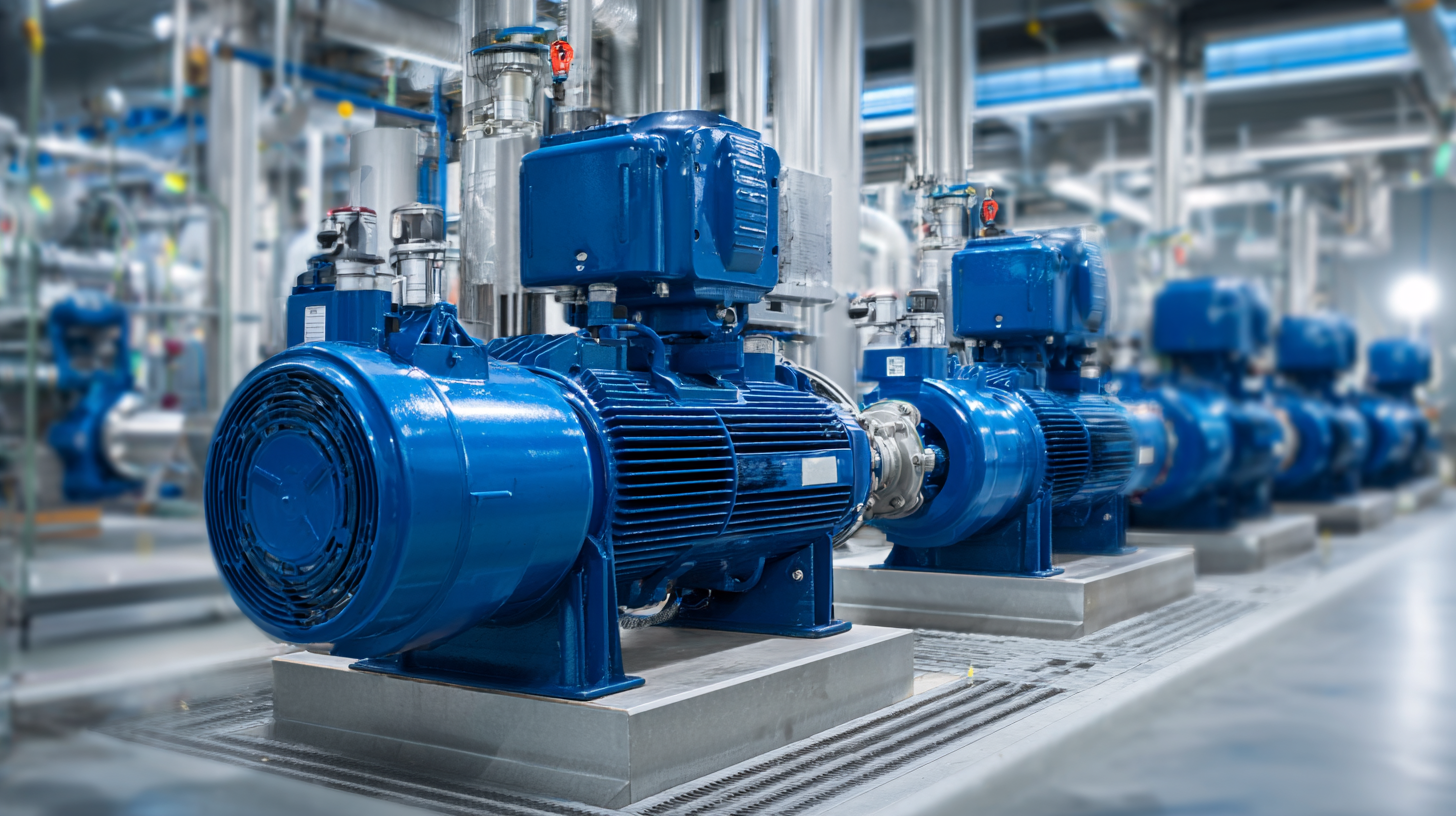

Types of Motor Pumps: Pros and Cons of Each Option

When it comes to selecting a motor pump, understanding the various types available and their respective advantages and disadvantages is essential for optimizing efficiency. Centrifugal pumps, for instance, are widely recognized for their ability to handle large volumes of fluid with high flow rates. According to the Hydraulic Institute, centrifugal pumps account for approximately 80% of the total pump market, largely due to their versatility and reliability in various applications. However, they may struggle with high-viscosity fluids and can lead to cavitation issues if not properly sized for the application.

On the other hand, positive displacement pumps offer distinct advantages in specific scenarios. These pumps excel in handling viscous fluids and provide a consistent flow rate regardless of pressure variations. A report by the Global Pump Market stated that positive displacement pumps are gaining traction, particularly in industries such as food processing and oil refining, where precision and reliability are paramount. Nonetheless, they can be less efficient than centrifugal pumps at higher flow rates, and their maintenance requirements may be more demanding, making it crucial to evaluate the operational context before making a choice.

Unlocking Efficiency: The Ultimate Guide to Choosing the Right Motor Pump for Your Needs

| Type of Motor Pump | Pros | Cons | Best Applications |

|---|---|---|---|

| Centrifugal Pump | High efficiency, simple design, suitable for large volumes | Less effective with viscous fluids, may require priming | Water supply, irrigation |

| Positive Displacement Pump | Handles viscous fluids well, provides consistent flow | Not suitable for high-speed applications, can be bulky | Chemical processing, food industry |

| Submersible Pump | Can operate underwater, effective for dewatering | Risk of overheating, limited depth capabilities | Flood control, drainage |

| Diaphragm Pump | Ideal for transferring corrosive liquids, self-priming | Lower flow rates, more maintenance required | Wastewater treatment, laboratory use |

| Gear Pump | Reliable for high-pressure applications, low shear | Can be expensive, limited to certain fluids | Lubrication, hydraulic systems |

Evaluating Efficiency: How to Measure the Performance of Motor Pumps

When choosing the right motor pump, evaluating efficiency becomes paramount for ensuring optimal performance. To measure the performance of motor pumps, one must consider several factors including flow rate, head pressure, and overall power consumption. Flow rate refers to the volume of fluid delivered by the pump in a specified time, while head pressure indicates the height that the pump can move the liquid against gravity. Accurate assessment of these elements is crucial as they directly relate to the energy usage and effectiveness of the pump.

Additionally, efficiency can be calculated by comparing the hydraulic power output to the electrical power input. This is where the concept of pump efficiency, often represented as a percentage, plays a critical role. High-efficiency pumps convert a greater portion of supplied energy into useful work, thus ensuring lower operational costs and reduced environmental impact. Regular performance evaluations and maintenance routines can also significantly enhance pump efficiency over time, making it essential for users to stay informed about the operational benchmarks relevant to their specific applications.

Maintenance Tips: Ensuring Longevity and Reliability of Your Motor Pump

Proper maintenance of motor pumps is essential for ensuring their longevity and reliability. Regular checks should be conducted to monitor for signs of wear and tear, including leaks or unusual noises. Keeping the motor pump clean is equally important; debris and buildup can hinder performance and lead to expensive repairs. A scheduled maintenance plan, which includes routine inspections and cleaning, helps prevent unexpected breakdowns.

Additionally, lubricating moving parts according to the manufacturer’s guidelines reduces friction and extends the life of the motor pump. It's also crucial to monitor the temperature of the motor during operation—overheating can indicate underlying issues that need immediate attention. Lastly, training staff on proper usage and troubleshooting basic problems can significantly enhance the pump's performance and lifespan, ensuring it operates at peak efficiency while minimizing downtime.