Our Blog

Check out our innovative pump solutions and industry insights to see what's new in the pumping industry. Stay up to date with the latest trends and news in the world of pumping technology by following our pumping technology blog.

- Home

- Blog

2025 How to Choose the Right Motor Pump for Your Needs

Choosing the right motor pump for your needs is an essential step that can significantly impact the efficiency and effectiveness of your operations. With the vast array of options available in the market, it is crucial to understand the specific requirements of your project to ensure you select a motor pump that meets those demands. From agricultural applications to industrial settings, motor pumps play a pivotal role in fluid transportation, making their selection paramount for successful outcomes.

In this guide, we will explore the key considerations to take into account when choosing a motor pump. Factors such as flow rate, pressure, power consumption, and the type of fluid being pumped are just the starting points when navigating the complexities of motor pump selection. Additionally, understanding the environment in which the pump will operate, along with maintenance needs and longevity, can further refine your options.

Ultimately, making an informed decision requires a comprehensive evaluation of your unique operational needs. By carefully assessing the available features and specifications of various motor pumps, you can ensure you invest in a solution that optimally supports your endeavors, balances performance with durability, and drives efficiency in your applications.

Choosing the Right Motor Pump: Understanding Types and Applications

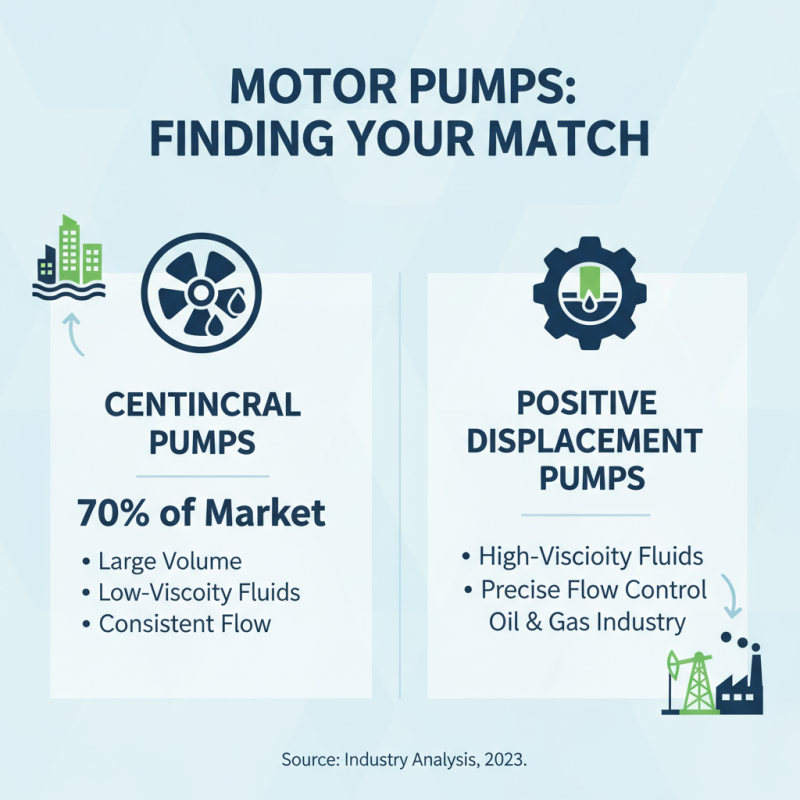

Choosing the right motor pump for your needs begins with understanding the various types and their applications. Motor pumps can be broadly categorized into centrifugal pumps and positive displacement pumps, each designed for specific tasks. Centrifugal pumps, which account for approximately 70% of the global pump market, are ideal for transporting large volumes of low-viscosity fluids at a consistent flow rate. In contrast, positive displacement pumps, used for higher-viscosity fluids, provide precise flow control and are essential in industries such as oil and gas where accuracy is critical.

When selecting a motor pump, consider factors like the fluid’s viscosity, the required flow rate, head pressure, and environmental conditions. According to a report from the Pump Manufacturers Association, improper pump selection can lead to a 20-30% increase in operational costs due to inefficiencies. It is essential to evaluate your specific application needs thoroughly.

Tips: Always consult with a pump selection expert or refer to detailed manufacturer data sheets before making a decision. Additionally, consider future scalability; choosing a versatile motor pump can save costs if your application requirements change. Assessing your needs with industry benchmarks can help in identifying the most suitable options, ensuring that you invest in a motor pump that will serve you efficiently over time.

Key Specifications to Consider When Selecting a Motor Pump

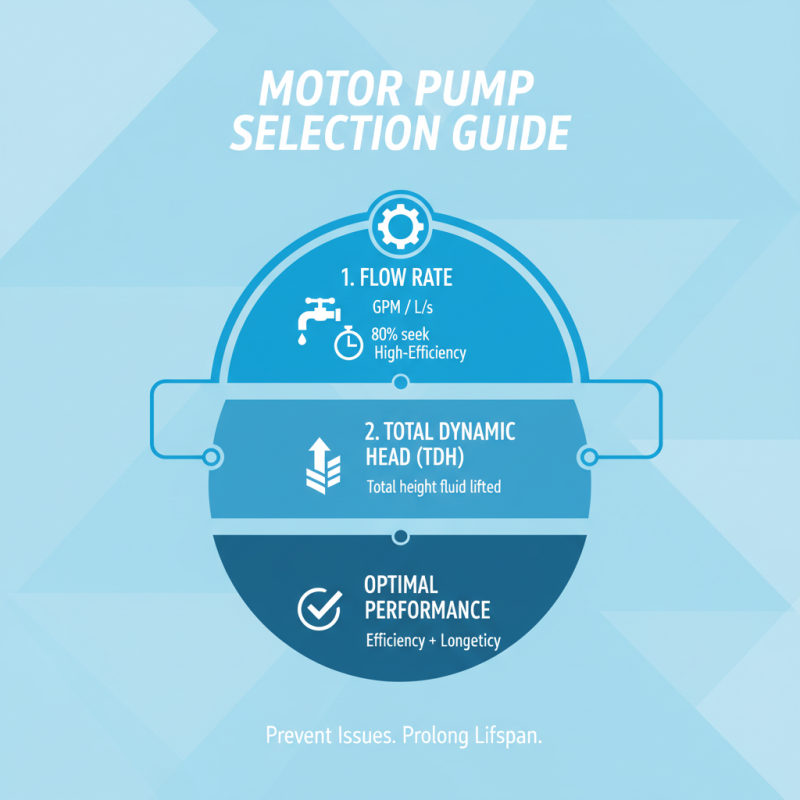

When selecting the right motor pump for your needs, understanding key specifications is essential to ensure optimal performance and efficiency. Start by considering the flow rate, which is typically measured in gallons per minute (GPM) or liters per second (L/s). According to recent industry data, the demand for high-efficiency pumps is increasing, with reports indicating that 80% of users are focused on maximizing flow rates without compromising energy consumption. A critical aspect of this is assessing the Total Dynamic Head (TDH), which refers to the total height that the pump needs to lift the fluid. Accurate TDH calculation can prevent operational issues and prolong the lifespan of the pump.

Another vital specification to look at is the pump’s power requirements, usually indicated in horsepower (HP). The efficiency of the pump's motor plays a significant role in determining energy costs over time. According to the U.S. Department of Energy, optimizing motor pump efficiency can lead to energy savings of 20-50%, significantly impacting operational expenditures. It's essential to choose a motor pump that matches your energy capacity while providing sufficient torque for your applications to avoid energy waste and enhance performance.

**Tips:** Always evaluate the operating conditions, such as fluid type and viscosity, which can heavily influence pump selection. Additionally, consider the maintenance requirements of the motor pump, as ease of maintenance can save time and reduce long-term costs. Finally, consulting with industry experts or utilizing professional design services can streamline the selection process, ensuring you choose a pump that best fits your operational needs and efficiency goals.

Evaluating Efficiency and Performance Ratings in Motor Pumps

When selecting a motor pump for your specific needs, understanding efficiency and performance ratings is crucial. Efficiency metrics, often expressed as a percentage, indicate how well a pump converts input power into usable output. According to the U.S. Department of Energy, highly efficient motor pumps can save businesses up to 30% in energy costs compared to less efficient models. Look for pumps that meet or exceed the American National Standards Institute (ANSI) standards, which specify that high-efficiency pumps should achieve at least 85% efficiency at full load.

Performance ratings, in addition to efficiency, play a vital role in guiding your choice. These ratings generally include parameters such as flow rate, pressure, and total dynamic head (TDH). The Hydraulic Institute's standards recommend that pumps should operate within their Best Efficiency Point (BEP) to maximize longevity and effectiveness. Operating outside this point can lead to excessive energy consumption and higher operational costs, sometimes by as much as 20% over the lifetime of the pump. By holistically evaluating both efficiency and performance ratings, users can make informed choices that enhance operational effectiveness and reduce long-term costs.

Assessing Cost vs. Long-term Value in Motor Pump Selection

When selecting a motor pump, it’s crucial to weigh cost against long-term value. Initially, a lower purchase price may seem attractive, but this can lead to higher expenses over time if the pump is inefficient or requires frequent repairs. Therefore, it's essential to consider not just the upfront cost, but also the projected operating costs, maintenance requirements, and the expected lifespan of the pump. Investing in a quality motor pump may offer superior efficiency, which can significantly reduce energy consumption and lower operating costs throughout its life.

Furthermore, evaluating long-term value involves considering the reliability and performance history of the motor pump. A pump that performs consistently and requires minimal downtime can translate to significant savings, not only in repairs but also in lost productivity. Therefore, it is advisable to conduct thorough research on various options, prioritize features such as durability and efficiency, and analyze the total cost of ownership. By focusing on both cost and long-term value, buyers can make informed decisions that ultimately lead to better performance and greater satisfaction with their motor pump selection.

2025 Motor Pump Selection: Cost vs. Long-term Value

This chart compares the initial costs and estimated lifetime values of motor pumps categorized by low, mid, and high cost. Selecting the right motor pump involves weighing both the upfront costs against potential long-term benefits to ensure optimal investment.

Top Industry Standards and Certifications for Reliable Motor Pumps

When selecting a motor pump, understanding the industry standards and certifications can significantly influence your decision. These standards ensure that the pumps meet essential safety, efficiency, and performance benchmarks. Look for certifications from recognized organizations such as ISO, CE, and UL. These certifications indicate that the motor pumps have undergone rigorous testing and meet specific quality requirements, providing peace of mind that you are investing in a reliable product.

Tips: Always verify the certifications listed by manufacturers. Ensure they are current and applicable to the specific type of motor pump you intend to purchase. This due diligence not only enhances safety but also extends the lifespan of the equipment.

Another critical aspect is to consider pumps that comply with environmental regulations and efficiency standards. Look for energy-efficient models that bear certifications such as ENERGY STAR or similar. These pumps not only minimize energy consumption but also help in reducing operational costs over time.

Tips: Evaluate the energy consumption rates of different models. Opting for energy-efficient pumps may result in significant savings in the long run, making them a worthwhile investment for your operations. By prioritizing industry standards and certifications, you can confidently choose a motor pump that fulfills your needs without compromising on quality.

2025 How to Choose the Right Motor Pump for Your Needs - Top Industry Standards and Certifications for Reliable Motor Pumps

| Parameter | Description | Industry Standard/Certification |

|---|---|---|

| Flow Rate | The volume of fluid the pump can move per unit of time. | ISO 9906 |

| Head Pressure | The height to which a pump can raise water. | ANSI/HI 9.6 |

| Efficiency | The ratio of useful output to total input in a process. | API 610 |

| Material | The substance from which the pump is made, affecting durability. | FDA 21 CFR |

| Noise Level | The sound produced by the pump during operation. | ISO 3744 |

| Power Supply | Type of energy required to operate the pump. | NEMA Standards |

Related Posts

-

Understanding the Innovations of Pump Manufacturers in Modern Industrial Applications

-

Exploring the Efficiency of Deep Well Pumps in Sustainable Agriculture Practices

-

2025 Top 10 Domestic Water Pumps: Unmatched Efficiency and Performance You Need!

-

2025 Guide: How to Choose the Best Small Submersible Pump for Your Needs

-

2025 Top 10 Deep Well Water Pumps: Ultimate Guide for Efficient Water Supply

-

Understanding the Benefits of Using a 1 Hp Well Pump for Efficient Water Supply