Our Blog

Check out our innovative pump solutions and industry insights to see what's new in the pumping industry. Stay up to date with the latest trends and news in the world of pumping technology by following our pumping technology blog.

- Home

- Blog

2026 How to Choose the Right Water Pumps for Your Project?

Choosing the right water pumps for your project is crucial. Water pumps play a vital role in various applications, from agriculture to construction. Selecting the appropriate pump can significantly impact efficiency and cost.

When evaluating water pumps, several factors come into play. These include flow rate, pressure requirements, and power source. Sometimes, the options can be overwhelming. Understanding your specific needs is essential. Pumping water isn't just about quantity; quality also matters.

Many projects face challenges in this area. There might be instances where the wrong pump was selected, leading to higher costs and inefficiency. Mistakes can happen. Reflecting on your choices can lead to better decisions in the future. Taking the time to analyze your project's requirements will ensure effective water management.

Understanding Different Types of Water Pumps: A Comprehensive Overview

When choosing water pumps, understanding the various types is crucial.

Centrifugal pumps are among the most common. They work by converting rotational energy into fluid movement. This design makes them ideal for clean water applications. However, they may struggle with thick, viscous fluids. If your project involves such materials, consider other options.

Positive displacement pumps are another type. They excel in moving thick fluids. These pumps trap a fixed amount of liquid and force it through the outlet. Their design allows for efficiency in various conditions. However, installing them can be tricky. They require precise calculations for optimal performance. The risk of over-pressurization is also higher, leading to potential failures.

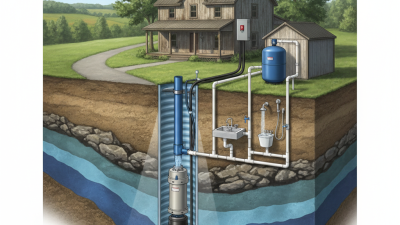

Submersible pumps are specifically designed for underwater use. Their sealed design prevents water damage. They are effective in drainage and sewage applications. Still, maintenance can be challenging. Accessing these pumps often requires dewatering the site. Choose the right type based on your specific project needs. Evaluate what works best for your situation, and acknowledge potential drawbacks.

Key Factors to Consider When Selecting Water Pumps for Your Project

When selecting the right water pump for your project, several key factors come into play. Understanding your specific needs is essential. Consider the volume of water to be pumped and the distance it needs to travel. Is it high pressure or low flow you require? The pump's capacity should align with your project demands.

Tip: Think about the environment where the pump will be used. Will it be in a clean or muddy area? This impacts the type and durability of the pump.

Power source is another important aspect. Electric pumps are common but may not work in remote or off-grid areas. A fuel-powered pump could be beneficial in such situations. Yet, think about maintenance. Fuel pumps often need more frequent checks compared to electric ones.

Tip: Don’t overlook noise levels. Some projects demand quiet operations. An overly loud pump can disturb the surrounding area.

Lastly, evaluate cost versus efficiency. Many pumps promise high efficiency at low prices. However, sometimes the cheapest option leads to constant repairs. Invest time in research, and assess user feedback carefully. It’s crucial to choose wisely, as you may not want to redo the installation soon after.

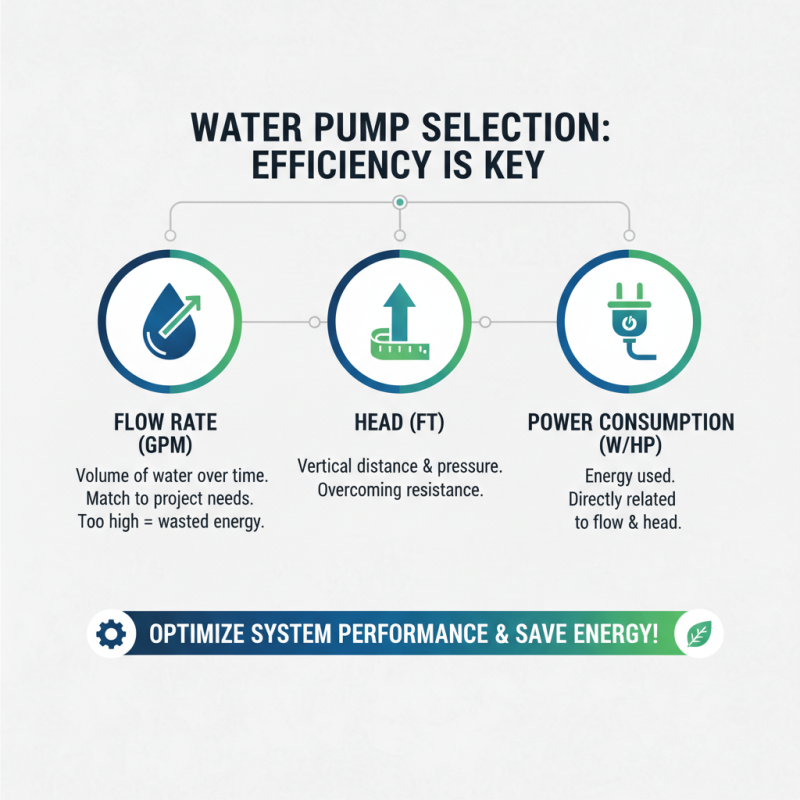

Evaluating Pump Efficiency: Flow Rate, Head, and Power Consumption

When selecting water pumps, efficiency is key. The flow rate, head, and power consumption are critical factors. Flow rate measures the volume of water a pump can move over time, typically in gallons per minute (GPM). According to industry reports, a flow rate that matches your project needs can enhance overall system performance. However, many overlook the implications of choosing a pump with too high a flow rate, potentially causing excessive energy use.

Head refers to the height a pump can lift water. It determines the pump’s ability to overcome resistance in the system. It’s crucial to assess the total dynamic head required for your application. A functional mismatch here can lead to operational inefficiencies. Many projects suffer from underestimating head requirements. This mistake can lead to pumps running at lower efficiency, wasting power, and reducing longevity.

Power consumption is often the final consideration, yet it should not be. The best pump is not always the most powerful. For instance, a pump operating at 75% efficiency will use significantly less energy than one at 50%. Data shows that energy costs can account for up to 90% of the total lifecycle cost of a pump. Therefore, understanding the balance among these elements—flow rate, head, and power consumption—is essential for any water pump project.

Importance of Material Selection in Water Pump Durability and Performance

When choosing water pumps, material selection is crucial. The durability of a pump greatly depends on the materials used in its construction. For instance, corrosion-resistant materials extend the lifespan of the pump, especially in harsh environments. Stainless steel is often preferred, yet it has higher costs. Sometimes, plastic may seem like a cheaper alternative, but it may not withstand temperature fluctuations well.

Pumps used in chemicals or saltwater face unique challenges. The right material must resist degradation. Failure to make a careful selection could lead to premature pump failure. This can result in costly downtime and repairs. It's worth considering the specific application and location. Sometimes, the most obvious choice falls short under actual conditions.

Conduct thorough research on different materials. Consider their thermal conductivity, hardness, and corrosion resistance. Don't overlook the environmental impact of your choices. Heavy materials might aid performance but have larger carbon footprints. In some cases, lighter materials could provide adequate performance with a smaller ecological impact. Reflect on these factors to ensure your project’s success.

Cost Analysis: Budgeting for Initial Purchase and Long-term Maintenance

Budgeting for water pumps requires a careful analysis. The initial purchase price is just the beginning. Consider the potential costs for installation. This often includes labor, piping, and electrical work. These can add up quickly, making the project more expensive than anticipated.

Long-term maintenance is another critical factor. Pumps need regular servicing to function efficiently. Neglect can lead to costly repairs. This might involve routine checks, parts replacement, or occasional overhauls. Some systems might require specialized knowledge, raising the maintenance cost.

It's essential to reflect on your project's specific needs. Size and capacity significantly impact both initial and ongoing expenses. Overestimating demand can lead to overspending. Conversely, underestimating can cause performance issues later. Keep these factors in mind while budgeting for your water pump project.

2026 Water Pumps Cost Analysis

This chart illustrates the initial purchase cost and annual maintenance cost for different types of water pumps. Understanding these costs can help you budget effectively for your project.

Related Posts

-

Top Water Pumps to Consider in 2025 for Your Home and Garden Needs

-

Top Water Pumps of 2025 for Every Need and Budget

-

How to Choose the Right 1hp Water Pump for Your Needs and Applications

-

Why You Should Use a Mini Water Pump for Your Home and Garden Needs?

-

Maximizing Efficiency: How Submersible Pumps Revolutionize Water Management in Agriculture

-

What is a 1 hp Well Pump and How Does it Work?