Our Blog

Check out our innovative pump solutions and industry insights to see what's new in the pumping industry. Stay up to date with the latest trends and news in the world of pumping technology by following our pumping technology blog.

- Home

- Blog

Why You Should Choose an Inline Water Pump for Your Water System Needs

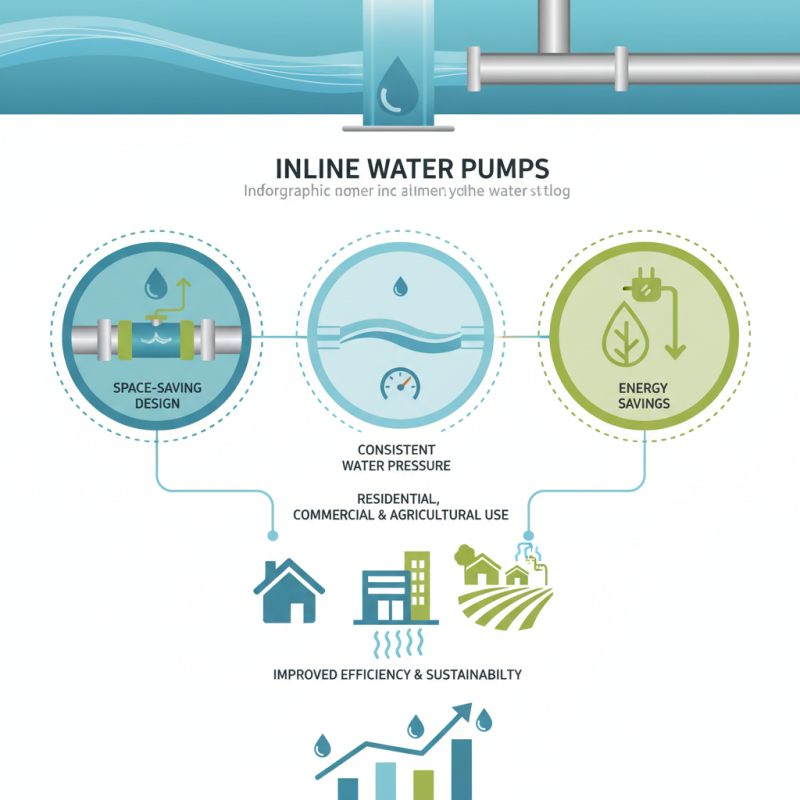

In the ever-evolving world of water systems, the choice of equipment can significantly impact efficiency and performance. An industry expert, Dr. Robert A. Smith, a leading mechanical engineer with over two decades of experience in fluid dynamics, emphasizes the importance of selecting the right components. He stated, "An inline water pump is not just an accessory; it is the backbone of an effective water distribution system." This assertion rings true as inline water pumps offer advantages that cater to various needs in residential, commercial, and agricultural settings.

When considering the various options available, the inline water pump stands out for its space-saving design and ability to deliver consistent water pressure. Unlike traditional pumps that may require extensive setup and maintenance, the inline configuration simplifies installation and operation. Furthermore, this type of pump can seamlessly integrate into existing systems, providing users with a reliable solution that can enhance overall water circulation and efficiency.

Adopting an inline water pump can lead to significant energy savings and improved functionality, making it an excellent choice for those looking to optimize their water systems. As technology progresses, the importance of utilizing advanced solutions like the inline water pump will only grow, ensuring that users meet their water needs effectively and sustainably.

Benefits of Using Inline Water Pumps for Efficient Water Flow

When considering a water system, the choice of an inline water pump can significantly enhance the efficiency of water flow. Inline water pumps are designed to be installed directly into the piping of a water distribution system, allowing for a streamlined and effective flow without the need for extensive modifications. This installation method minimizes disruptions to existing landscapes or buildings, making them ideal for both new constructions and retrofits in residential or commercial settings.

One of the primary benefits of using inline water pumps is their ability to maintain consistent pressure throughout the system. This ensures that all fixtures receive adequate water supply, reducing the risk of fluctuations that can lead to inefficiencies or reduced performance. Additionally, because inline pumps can be mounted horizontally or vertically, they offer versatility in installation options, fitting into tighter spaces and optimizing system layout. Their energy efficiency further means lower operating costs, contributing to a more sustainable water system without sacrificing performance.

Benefits of Using Inline Water Pumps for Efficient Water Flow

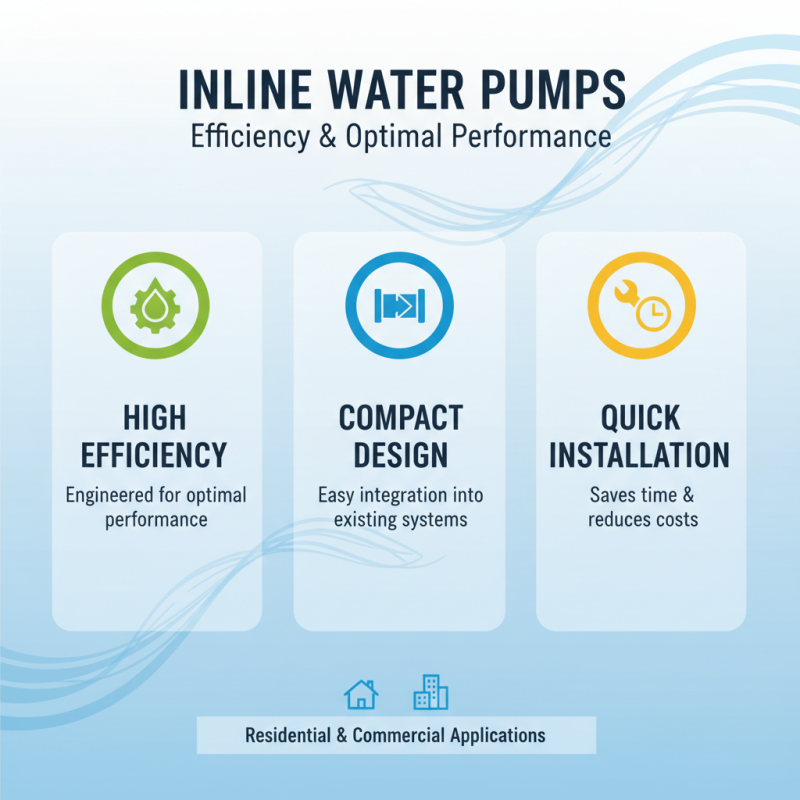

Key Features of Inline Water Pumps That Enhance Performance

Inline water pumps are engineered for efficiency and optimal performance, making them an excellent choice for various water system applications. One of the standout features of these pumps is their compact design, which allows for easier integration into existing piping systems without requiring extensive modifications. This design simplicity not only saves space but also reduces installation time and costs, making it an attractive option for both residential and commercial setups.

Another key feature of inline water pumps is their enhanced flow rate capabilities. These pumps are designed to maintain steady and consistent water flow, which is essential for applications that demand reliability, such as irrigation systems, aquariums, or industrial processes. The ability to operate quietly and with minimal vibration further adds to their appeal, ensuring that users can benefit from efficient performance without compromising on comfort or peace in their environment. Additionally, many inline pumps come equipped with advanced motor technologies that improve energy efficiency, leading to reduced operating costs over time.

Comparative Analysis: Inline Water Pumps vs. Other Pump Types

Inline water pumps have gained significant traction in various applications due to their efficiency and design advantages over other pump types. According to a report from the Hydraulic Institute, inline pumps typically offer higher hydraulic efficiency, often ranging between 70% to 90%, compared to traditional centrifugal pumps, which can fall between 50% to 70%. This efficiency translates to lower operational costs, making inline pumps a preferred choice for many commercial and industrial water systems.

When comparing inline water pumps to submersible and centrifugal pumps, the latter two tend to have limitations in terms of space and maintenance. Inline pumps can be easily integrated into existing water systems without requiring extensive modifications. Furthermore, the lack of a motor submerged in fluid means reduced wear and tear, leading to a longer operational lifespan. The American Society of Mechanical Engineers (ASME) reports that regular maintenance intervals for inline pumps can be reduced by up to 30% compared to submersible varieties, which often require extensive checks due to their submerged nature. This lower maintenance demand not only enhances convenience but also sustains system reliability over time.

Why You Should Choose an Inline Water Pump for Your Water System Needs - Comparative Analysis: Inline Water Pumps vs. Other Pump Types

| Pump Type | Efficiency (%) | Installation Cost ($) | Maintenance Frequency (per year) | Lifespan (years) | Noise Level (dB) |

|---|---|---|---|---|---|

| Inline Water Pump | 85 | 1500 | 1 | 15 | 60 |

| Submersible Pump | 80 | 1200 | 2 | 10 | 70 |

| Centrifugal Pump | 78 | 1000 | 3 | 8 | 75 |

| Positive Displacement Pump | 82 | 1300 | 4 | 12 | 65 |

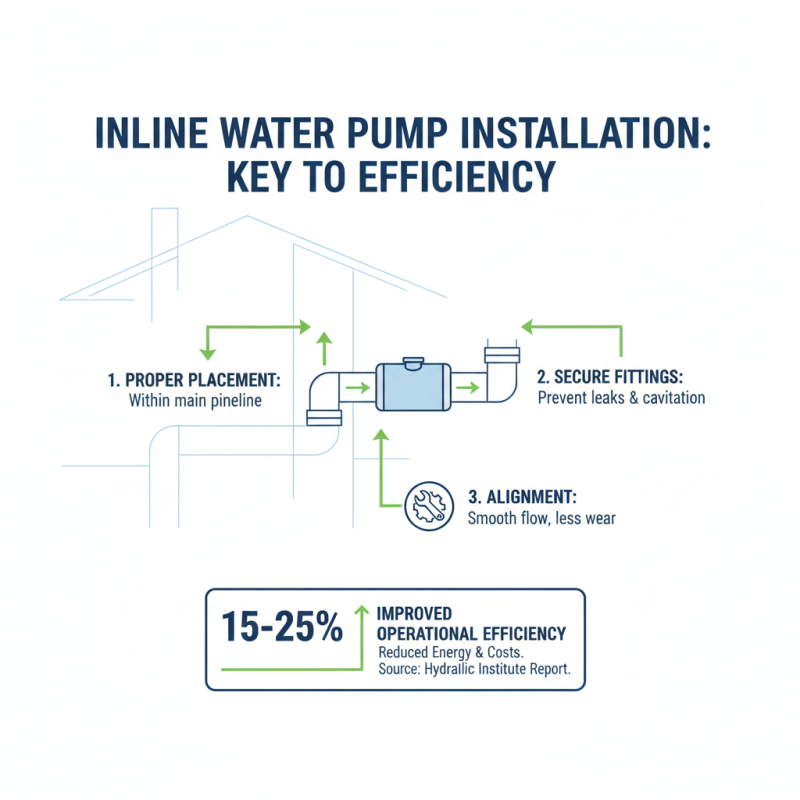

Installation Considerations for Inline Water Pumps in Water Systems

When considering an inline water pump for your water system, installation is a critical factor that can significantly influence the overall performance and efficiency of your system. Inline water pumps, which are designed to be installed within the water pipeline, provide several advantages including space-saving designs and enhanced flow rates. According to a report from the Hydraulic Institute, proper installation can improve the operational efficiency of these pumps by 15-25%, reducing energy consumption and operational costs.

One of the key installation considerations is the positioning of the pump within the system. It is essential to install the pump in a location that minimizes bends and turns in the piping to reduce friction losses. Industry guidelines suggest maintaining a minimum of 10 pipe diameters of straight pipe length before and after the pump to ensure optimal performance. Additionally, ensuring that the pump is not exposed to potential cavitation points—areas where the pressure might drop below the liquid’s vapor pressure—is vital for maintaining longevity and efficiency. A study by the American Society of Mechanical Engineers highlights that inadequate installation can lead to a 30% decrease in pumping efficiency, reiterating the need for careful planning and execution.

Finally, while installing inline pumps, attention must also be given to the compatibility of the pump materials with the fluids being transported, as improper material choice can lead to corrosion and pump failure. Selecting pumps made from corrosion-resistant materials based on the specific application not only enhances durability but also contributes to lower maintenance costs over time. Adhering to these installation considerations will optimize the functionality of inline water pumps and ensure a reliable water system.

Maintenance Tips for Prolonging the Life of Inline Water Pumps

When it comes to maintaining inline water pumps, regular inspection and servicing are crucial for ensuring their longevity and efficiency. One key aspect of maintenance is checking for any signs of wear or damage. This includes examining the pump's seals, bearings, and impellers for any deterioration that might affect performance. Additionally, keeping an eye on the pump's performance metrics, such as flow rate and pressure, can help identify potential issues before they escalate, allowing for timely repairs or replacements.

Another important maintenance tip is to ensure that the pump is properly lubricated, as this reduces friction and wear on moving parts. Depending on the pump's specifications, use appropriate lubricants and follow manufacturer guidelines for frequency and type. It’s also essential to maintain a clean environment around the pump, as debris and dirt can lead to clogs and operational inefficiencies. Regular cleaning and scheduled maintenance checks can prevent unexpected breakdowns, keeping your water system operating smoothly for years to come.

Related Posts

-

2025 How to Choose the Best Submersible Well Pump for Your Water Needs

-

Maximizing Efficiency: How Submersible Pumps Revolutionize Water Management in Agriculture

-

Top 5 Benefits of Upgrading Your Well Pumps for Improved Water Quality and Efficiency

-

10 Best Mini Water Pumps for Efficient Water Transfer in 2023

-

Understanding the Innovations of Pump Manufacturers in Modern Industrial Applications

-

How to Choose the Right 1hp Water Pump for Your Needs and Applications