Our Blog

Check out our innovative pump solutions and industry insights to see what's new in the pumping industry. Stay up to date with the latest trends and news in the world of pumping technology by following our pumping technology blog.

- Home

- Blog

Top 10 Benefits of Submersible Motors for Efficient Pumping Solutions?

In today's world, efficient pumping solutions are vital for numerous industries. Submersible motors have become a key technology in this area. According to Dr. Emily Carter, a leading expert in fluid dynamics, "Submersible motors revolutionize the way we approach fluid movement." Her insights reflect the growing reliance on this technology.

Submersible motors operate underwater, enhancing efficiency and minimizing energy loss. They are designed to withstand harsh environments. This design feature is a significant advantage over traditional motors. Industries ranging from agriculture to wastewater management benefit from their use. However, some still question the initial costs and complexity of installation.

Despite these concerns, the benefits are undeniable. Submersible motors offer improved efficiency, reducing operational costs over time. Their compact design allows for easy integration into existing systems. As we explore the top ten benefits of submersible motors, it’s essential to think critically about both their advantages and potential drawbacks.

Top Advantages of Submersible Motors in Pumping Efficiency

Submersible motors play a crucial role in enhancing pumping efficiency. Many industries benefit from their unique design, which allows them to operate underwater. According to a recent report by the International Pump Users Association, submersible motors can reduce energy consumption by up to 30%. This efficiency is vital for sectors like agriculture and wastewater management.

The ability to install submersible motors deep within the water source minimizes energy loss during pumping. A study from the Hydraulic Institute found that these systems can achieve a pump efficiency of over 85%, particularly in deep well applications. However, there are exceptions; not all installations yield the same benefits. Understanding the specific water source conditions is essential for optimal performance.

The compact nature of submersible motors saves valuable space in facilities. Yet, maintenance practices can be challenging in harsh environments, raising operational concerns. Regular inspections are necessary to prevent failures that could halt operations. Industry experts recommend implementing preventive maintenance schedules to address these potential issues proactively. By doing so, businesses can ensure longer operational lifespans for their submersible motor systems.

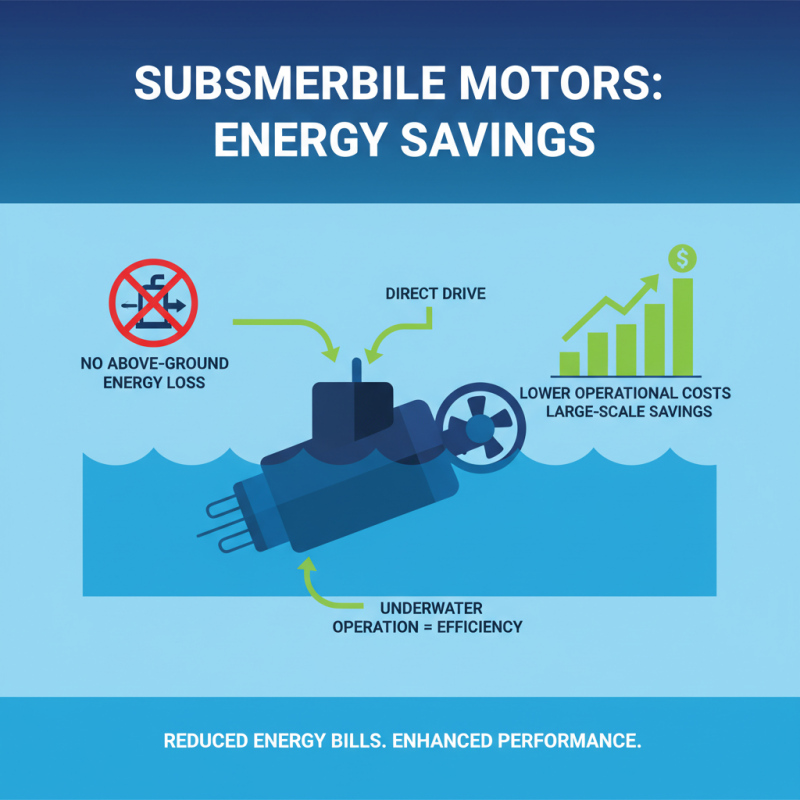

Energy Savings: How Submersible Motors Reduce Operational Costs

Submersible motors present an excellent solution for efficient pumping. One of their standout features is energy savings. They operate underwater, eliminating energy loss typically encountered with above-ground pumps. By directly driving the pump, they enhance performance while reducing energy costs. This efficiency leads to lower operational expenses over time. Businesses can see significant savings, especially in large-scale operations.

Consider these tips for maximizing energy savings with submersible motors. Regular maintenance is crucial. Check seals and bearings often to prevent leaks. A small leak can significantly increase energy consumption. Adjust settings for optimal performance based on usage demands. Overperformance can waste energy and drive costs up.

Monitoring your energy usage is vital. Use tools to track consumption patterns. Identifying trends helps in making informed decisions. If energy consumption spikes unexpectedly, investigate the cause promptly. Small issues can lead to larger, costlier problems if ignored. Regularly review operational processes and make adjustments for maximum efficiency.

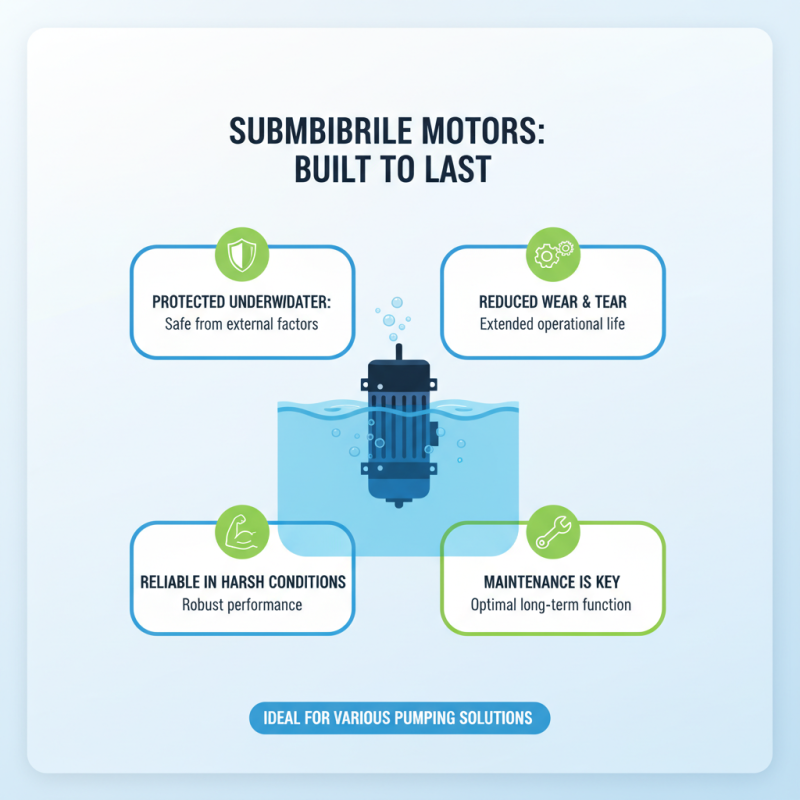

Durability and Longevity: The Performance of Submersible Motors

Submersible motors offer remarkable durability and longevity, making them ideal for various pumping solutions. Their design allows them to operate underwater, which protects them from external environmental factors. This feature significantly reduces wear and tear, extending their operational life. Users often find these motors reliable even in harsh conditions. However, maintenance is crucial to ensure they function optimally over time.

One common issue with submersible motors is overheating. Proper ventilation can help mitigate this risk. Regular checks are necessary to monitor temperature levels. Additionally, the materials used in submersible motors can influence their lifespan. Corrosion-resistant coatings are essential for motors exposed to aggressive environments. Despite these advancements, some users may overlook routine maintenance. This can lead to performance decline, ultimately reducing longevity.

When evaluating the performance of submersible motors, it's essential to consider these factors. Investing in quality materials and regular upkeep will maximize their efficiency. Ultimately, understanding these aspects can enhance the reliability of pumping solutions.

Versatility in Installation: Adapting Submersible Motors to Various Environments

Submersible motors are incredibly versatile in their installation, making them suitable for numerous environments. Whether in deep wells, water treatment plants, or industrial applications, these motors adapt well. Their compact design allows for easy fitting in tight spaces. They can operate submerged in various fluids, making them ideal for unique pumping needs.

However, the adaptability of submersible motors does not come without challenges. For instance, installation in harsh conditions may lead to technical issues. The presence of contaminants can impact performance over time. Users should regularly maintain their systems to avoid failures. Understanding the environment is crucial for optimal operation. Selecting the right motor type can be a complex decision.

In certain scenarios, modifications are necessary for efficient functioning. Installing additional protective measures can enhance motor longevity. Yet, not all adaptations will yield positive results; careful consideration is key. Always review your specific needs and environment before making changes. This reflects the importance of thorough planning in ensuring optimal pumping solutions.

Top 10 Benefits of Submersible Motors for Efficient Pumping Solutions

Enhanced Performance: Maximizing Flow Rates with Submersible Motors

Submersible motors are transforming the pumping industry with their incredible efficiency. Enhanced performance is one of the standout benefits. These motors are designed to operate underwater, which optimizes their flow rates. The result? Increased productivity in various applications, from agricultural irrigation to municipal water supply.

When it comes to maximizing flow rates, the design of submersible motors plays a vital role. They reduce friction and energy loss, ensuring more fluid movement through the system. Imagine a serene pond. A submersible motor can pump water quietly from its depths, minimizing noise pollution and enhancing energy efficiency. However, not every situation is ideal. In some cases, the initial installation and maintenance can be challenging. Proper training is essential to avoid operational mishaps.

Moreover, submersible motors can handle different fluids, adapting to various needs. This versatility can lead to unexpected benefits and challenges. For instance, while they can efficiently manage wastewater, the remnants can affect motor longevity. A reflective approach is crucial. Understanding these nuances can mean the difference between long-term reliability and costly repairs.

Related Posts

-

Essential Guide to Choosing the Perfect Well Water Pump for Your Home Needs

-

10 Best Mini Water Pumps for Efficient Water Transfer in 2023

-

Top Water Pumps to Consider in 2025 for Your Home and Garden Needs

-

Top 10 Tips for Choosing the Best Small Submersible Pump for Your Needs

-

Top 10 Bore Pump Types for Efficient Water Extraction Techniques

-

Best Small Water Pump Options for 2026 What Should You Know?